Optimized manufacturing and new service business with Industrial IoT

In today's data-driven business world, industrial companies face the central challenge of gaining valuable insights from operational data. CONTACT Elements for IoT helps to collect and understand data efficiently and integrate it into automated processes. Manage assets precisely, optimize manufacturing processes, and strengthen your service business through customized digital services. With CONTACT Elements for IoT, you are shaping not only the present but also the future success of your company.

CONTACT Elements for IoT paves the way for a smooth start for all companies, regardless of their level of digital maturity, and enables them to scale gradually according to their individual needs:

In today's data-driven business world, industrial companies face the central challenge of gaining valuable insights from operational data. CONTACT Elements for IoT helps to collect and understand data efficiently and integrate it into automated processes. Manage assets precisely, optimize manufacturing processes, and strengthen your service business through customized digital services. With CONTACT Elements for IoT, you are shaping not only the present but also the future success of your company.

CONTACT Elements for IoT paves the way for a smooth start for all companies, regardless of their level of digital maturity, and enables them to scale gradually according to their individual needs:

In today's data-driven business world, industrial companies face the central challenge of gaining valuable insights from operational data. CONTACT Elements for IoT helps to collect and understand data efficiently and integrate it into automated processes. Manage assets precisely, optimize manufacturing processes, and strengthen your service business through customized digital services. With CONTACT Elements for IoT, you are shaping not only the present but also the future success of your company.

CONTACT Elements for IoT paves the way for a smooth start for all companies, regardless of their level of digital maturity, and enables them to scale gradually according to their individual needs:

Industrial IoT for shopfloor management and condition monitoring

The high-tech specialist Kübler uses Elements for IoT for more than just shopfloor management and condition monitoring in production. Find out how Kübler integrates PLM and IoT into a closed-loop process and provides its customers genuine added value through the digital nameplate.

Industrial IoT for shopfloor management and condition monitoring

The high-tech specialist Kübler uses Elements for IoT for more than just shopfloor management and condition monitoring in production. Find out how Kübler integrates PLM and IoT into a closed-loop process and provides its customers genuine added value through the digital nameplate.

The high-tech specialist Kübler uses Elements for IoT for more than just shopfloor management and condition monitoring in production. Find out how Kübler integrates PLM and IoT into a closed-loop process and provides its customers genuine added value through the digital nameplate.

Why CONTACT Elements for IoT?

No/low code IoT platform

CONTACT Elements for IoT stands out with its flexibility, quick onboarding and individual expandability, no matter how digitalized your company is. Thanks to our modular system and the no/low-code principle, you can easily add desired functions to the platform without any complex programming.

No/low code IoT platform

CONTACT Elements for IoT stands out with its flexibility, quick onboarding and individual expandability, no matter how digitalized your company is. Thanks to our modular system and the no/low-code principle, you can easily add desired functions to the platform without any complex programming.

CONTACT Elements for IoT stands out with its flexibility, quick onboarding and individual expandability, no matter how digitalized your company is. Thanks to our modular system and the no/low-code principle, you can easily add desired functions to the platform without any complex programming.

"Their modular, flexible platform – CONTACT Elements for IoT – is easily implemented. Industrial companies who are committed to the use of IIoT are encouraged to review and evaluate the CONTACT Software solution."

CIMdata, Inc. über CONTACT Elements for IoT, August 2023

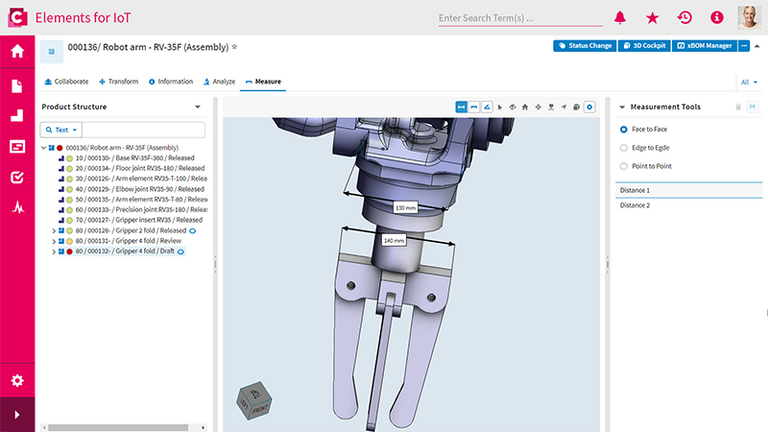

Digital twin as a key component

Elements for IoT offers a precise overview of the condition of your assets through digital twins. Field and sensor data from systems, software and hardware configurations, 3D models, and maintenance histories – all are brought together in a single source of truth. These virtual representations form the core of all data-driven processes, providing continuous insight into your assets' history and current state at any given time.

Digital twin as a key component

Elements for IoT offers a precise overview of the condition of your assets through digital twins. Field and sensor data from systems, software and hardware configurations, 3D models, and maintenance histories – all are brought together in a single source of truth. These virtual representations form the core of all data-driven processes, providing continuous insight into your assets' history and current state at any given time.

Elements for IoT offers a precise overview of the condition of your assets through digital twins. Field and sensor data from systems, software and hardware configurations, 3D models, and maintenance histories – all are brought together in a single source of truth. These virtual representations form the core of all data-driven processes, providing continuous insight into your assets' history and current state at any given time.

Integration of AI technology

The automation of business processes relies heavily on detecting anomalies in datasets and information. CONTACT actively utilizes AI mechanisms to identify outliers and irregularities, thereby enhancing transparency in industrial operations. Particularly, predictive insights, such as forecasts for the behavior and condition of plants and components, provide additional value. They enable longer warning times, prevent unplanned downtime, and improve monitoring coverage.

Integration of AI technology

The automation of business processes relies heavily on detecting anomalies in datasets and information. CONTACT actively utilizes AI mechanisms to identify outliers and irregularities, thereby enhancing transparency in industrial operations. Particularly, predictive insights, such as forecasts for the behavior and condition of plants and components, provide additional value. They enable longer warning times, prevent unplanned downtime, and improve monitoring coverage.

The automation of business processes relies heavily on detecting anomalies in datasets and information. CONTACT actively utilizes AI mechanisms to identify outliers and irregularities, thereby enhancing transparency in industrial operations. Particularly, predictive insights, such as forecasts for the behavior and condition of plants and components, provide additional value. They enable longer warning times, prevent unplanned downtime, and improve monitoring coverage.

Comprehensive energy management

CONTACT Elements for IoT enables the implementation of energy management software, facilitating effective energy monitoring through robust features and informative dashboards. Capture energy data, identify energy-intensive assets, and implement targeted efficiency-enhancing measures.

Comprehensive energy management

CONTACT Elements for IoT enables the implementation of energy management software, facilitating effective energy monitoring through robust features and informative dashboards. Capture energy data, identify energy-intensive assets, and implement targeted efficiency-enhancing measures.

CONTACT Elements for IoT enables the implementation of energy management software, facilitating effective energy monitoring through robust features and informative dashboards. Capture energy data, identify energy-intensive assets, and implement targeted efficiency-enhancing measures.

Connectivity and interoperability

By using standard protocols such as OPC UA, MQTT and PPMP, and aligning with the Industry 4.0 platform’s standards, Elements for IoT gives machines and systems a voice: they can communicate with the operator or other IT systems. Strengthen the role of your machines by actively integrating them into automated business processes using the Asset Administration Shell. Thanks to standard interfaces and powerful integration technology, we ensure seamless connections across system and application boundaries for end-to-end processes in your industrial transformation.

Connectivity and interoperability

By using standard protocols such as OPC UA, MQTT and PPMP, and aligning with the Industry 4.0 platform’s standards, Elements for IoT gives machines and systems a voice: they can communicate with the operator or other IT systems. Strengthen the role of your machines by actively integrating them into automated business processes using the Asset Administration Shell. Thanks to standard interfaces and powerful integration technology, we ensure seamless connections across system and application boundaries for end-to-end processes in your industrial transformation.

By using standard protocols such as OPC UA, MQTT and PPMP, and aligning with the Industry 4.0 platform’s standards, Elements for IoT gives machines and systems a voice: they can communicate with the operator or other IT systems. Strengthen the role of your machines by actively integrating them into automated business processes using the Asset Administration Shell. Thanks to standard interfaces and powerful integration technology, we ensure seamless connections across system and application boundaries for end-to-end processes in your industrial transformation.

Know-how and consulting

CONTACT is your partner for the introduction and implementation of customized digitalization solutions. In addition to the software, we offer comprehensive consulting services in pre-designed packages:

• Consulting

• Implementation

• Training

• Proof of Concept

Know-how and consulting

CONTACT is your partner for the introduction and implementation of customized digitalization solutions. In addition to the software, we offer comprehensive consulting services in pre-designed packages:

• Consulting

• Implementation

• Training

• Proof of Concept

CONTACT is your partner for the introduction and implementation of customized digitalization solutions. In addition to the software, we offer comprehensive consulting services in pre-designed packages:

• Consulting

• Implementation

• Training

• Proof of Concept

Powerful IoT-Partners

The complete IoT platform – powered by CONTACT Elements

Powered by CONTACT Elements means: You use the most advanced platform and technology worldwide to connect the physical and digital realms. As flexible as Lego, the modular principle of CONTACT Elements represents solutions that surpass the sum of their parts: outstanding individually, unique in combination.