Benefits

- Accelerate change processes through digital workflows and standards

- Simplify work with digital folders and Task Manager

- Map change processes easily and flexibly and benefit from end-to-end documentation

- Validate the analysis of technical changes using 3D models

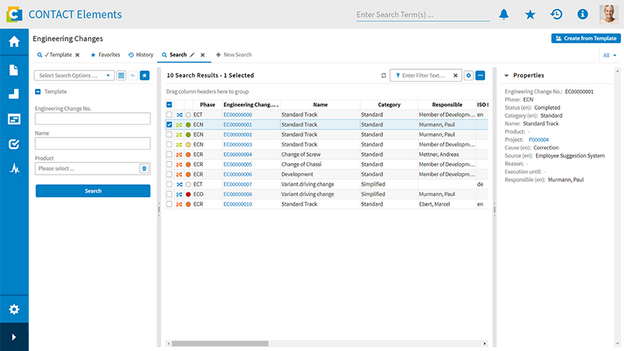

Accelerate your change processes through digital workflows and standards

Technical changes account for up to 50 percent of development costs! This means that there is great potential for cost reductions and faster market launch. With CONTACT's Engineering Change (EC), you can control changes to your products flexibly and reliably: Change processes have their own status-controlled lifecycle. Templates for the verification measures that are appropriate for the company provide users with workflows for optimum process implementation, for example on the basis of the level of maturity of the product.

System-controlled push effect

Use digitalization to speed up your change processes compared with paper-based processes. Engineering Change supports your processes through workflow push via e-mail and integrated task management. Speed up the process by processing parallel branches of the workflow and automatically supply specialist departments such as Development, Tool and Model Making or Production Planning with the current development statuses. Take advantage of the benefits of automated processes such as the batch release of CAD models and parts or the computation of the configuration of test processes, for example on the basis of the product type and level of maturity.

Accelerate your change processes through digital workflows and standards

Technical changes account for up to 50 percent of development costs! This means that there is great potential for cost reductions and faster market launch. With CONTACT's Engineering Change (EC), you can control changes to your products flexibly and reliably: Change processes have their own status-controlled lifecycle. Templates for the verification measures that are appropriate for the company provide users with workflows for optimum process implementation, for example on the basis of the level of maturity of the product.

System-controlled push effect

Use digitalization to speed up your change processes compared with paper-based processes. Engineering Change supports your processes through workflow push via e-mail and integrated task management. Speed up the process by processing parallel branches of the workflow and automatically supply specialist departments such as Development, Tool and Model Making or Production Planning with the current development statuses. Take advantage of the benefits of automated processes such as the batch release of CAD models and parts or the computation of the configuration of test processes, for example on the basis of the product type and level of maturity.

Technical changes account for up to 50 percent of development costs! This means that there is great potential for cost reductions and faster market launch. With CONTACT's Engineering Change (EC), you can control changes to your products flexibly and reliably: Change processes have their own status-controlled lifecycle. Templates for the verification measures that are appropriate for the company provide users with workflows for optimum process implementation, for example on the basis of the level of maturity of the product.

System-controlled push effect

Use digitalization to speed up your change processes compared with paper-based processes. Engineering Change supports your processes through workflow push via e-mail and integrated task management. Speed up the process by processing parallel branches of the workflow and automatically supply specialist departments such as Development, Tool and Model Making or Production Planning with the current development statuses. Take advantage of the benefits of automated processes such as the batch release of CAD models and parts or the computation of the configuration of test processes, for example on the basis of the product type and level of maturity.

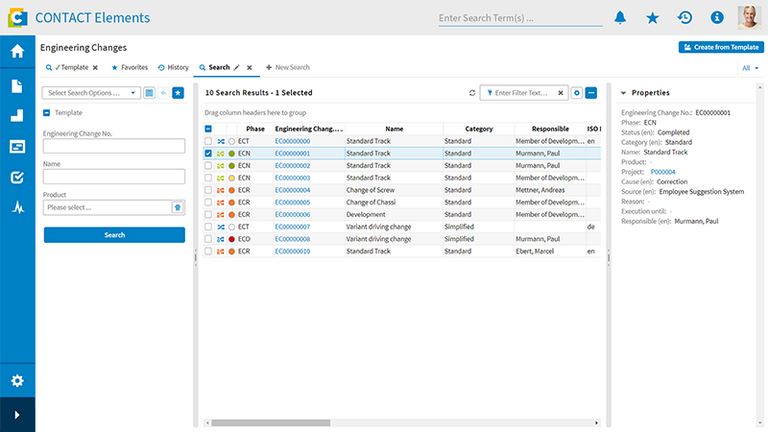

Simplify your employees' work with digital folders and Task Manager

Workflow-assisted process control combined with digital change folders provides maximum transparency. The folders contain all the information and documents needed to assess and implement a technical change. They give all participants at all sites worldwide direct access to all the necessary models, documents and information in lines with their individual permissions.

Task Manager

Depending on the product group and level of product maturity, your employees examine and process changes from different perspectives, for example with regard to costs, customer acceptance, factory assignment, compliance, etc. The EC templates, together with your rules on variants, make sure that all employees are supplied with the corresponding verification and release tasks according to their specific roles. This is possible thanks to the Task Manager, which indicates all the tasks that are relevant to them, provides direct access to the required documents and information, and makes the corresponding activities possible.

Simplify your employees' work with digital folders and Task Manager

Workflow-assisted process control combined with digital change folders provides maximum transparency. The folders contain all the information and documents needed to assess and implement a technical change. They give all participants at all sites worldwide direct access to all the necessary models, documents and information in lines with their individual permissions.

Task Manager

Depending on the product group and level of product maturity, your employees examine and process changes from different perspectives, for example with regard to costs, customer acceptance, factory assignment, compliance, etc. The EC templates, together with your rules on variants, make sure that all employees are supplied with the corresponding verification and release tasks according to their specific roles. This is possible thanks to the Task Manager, which indicates all the tasks that are relevant to them, provides direct access to the required documents and information, and makes the corresponding activities possible.

Workflow-assisted process control combined with digital change folders provides maximum transparency. The folders contain all the information and documents needed to assess and implement a technical change. They give all participants at all sites worldwide direct access to all the necessary models, documents and information in lines with their individual permissions.

Task Manager

Depending on the product group and level of product maturity, your employees examine and process changes from different perspectives, for example with regard to costs, customer acceptance, factory assignment, compliance, etc. The EC templates, together with your rules on variants, make sure that all employees are supplied with the corresponding verification and release tasks according to their specific roles. This is possible thanks to the Task Manager, which indicates all the tasks that are relevant to them, provides direct access to the required documents and information, and makes the corresponding activities possible.

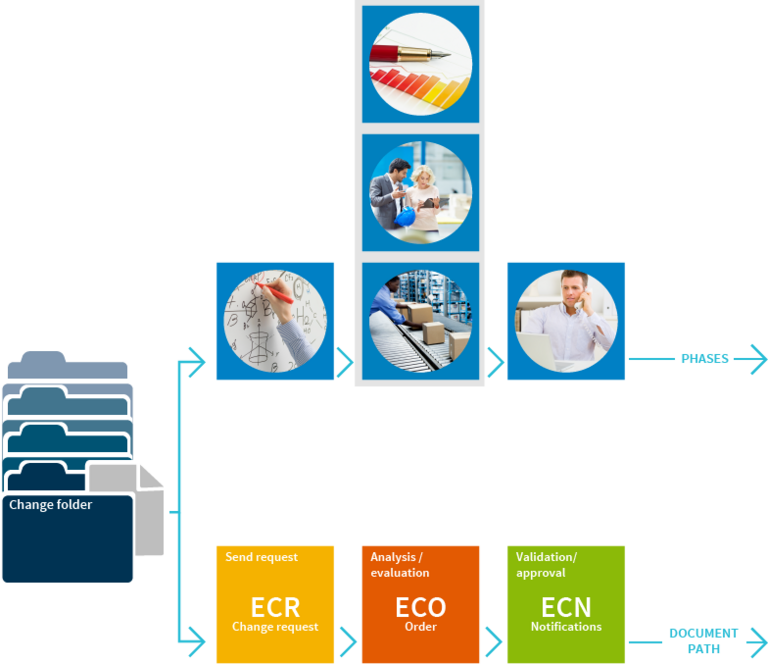

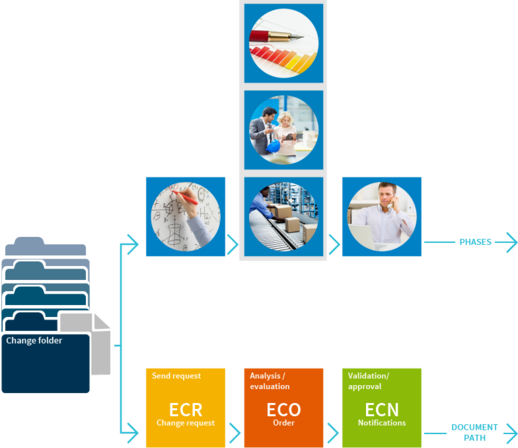

Validate the analysis of technical changes using 3D models

CONTACT Engineering Change is flexible and easy to configure. Thanks to the appropriate switch settings and templates, change processes can be mapped in a way that takes account of the special requirements of any given industry – for example FDA regulations in the medical engineering field or SASIG recommendations in the automotive sector. In this way, you can adapt industry-specific regulations and guidelines precisely to meet your own specific requirements within the framework of the proven ECR/ECO/ECN logic. With Engineering Change, you benefit from the effective control and monitoring of the change process combined with an outstanding level of flexibility.

In-process documentation

Engineering Change not only offers standardized processes and transparent processing sequences but also end-to-end documentation. Your employees do not have to record information separately in order to comply with the various documentary requirements, e.g. within the framework of the Machine Directive. These and other compliance requirements are fulfilled automatically thanks to the accompanying "in-process" documentation. We call this principle "compliance in process".

Validate the analysis of technical changes using 3D models

CONTACT Engineering Change is flexible and easy to configure. Thanks to the appropriate switch settings and templates, change processes can be mapped in a way that takes account of the special requirements of any given industry – for example FDA regulations in the medical engineering field or SASIG recommendations in the automotive sector. In this way, you can adapt industry-specific regulations and guidelines precisely to meet your own specific requirements within the framework of the proven ECR/ECO/ECN logic. With Engineering Change, you benefit from the effective control and monitoring of the change process combined with an outstanding level of flexibility.

In-process documentation

Engineering Change not only offers standardized processes and transparent processing sequences but also end-to-end documentation. Your employees do not have to record information separately in order to comply with the various documentary requirements, e.g. within the framework of the Machine Directive. These and other compliance requirements are fulfilled automatically thanks to the accompanying "in-process" documentation. We call this principle "compliance in process".

CONTACT Engineering Change is flexible and easy to configure. Thanks to the appropriate switch settings and templates, change processes can be mapped in a way that takes account of the special requirements of any given industry – for example FDA regulations in the medical engineering field or SASIG recommendations in the automotive sector. In this way, you can adapt industry-specific regulations and guidelines precisely to meet your own specific requirements within the framework of the proven ECR/ECO/ECN logic. With Engineering Change, you benefit from the effective control and monitoring of the change process combined with an outstanding level of flexibility.

In-process documentation

Engineering Change not only offers standardized processes and transparent processing sequences but also end-to-end documentation. Your employees do not have to record information separately in order to comply with the various documentary requirements, e.g. within the framework of the Machine Directive. These and other compliance requirements are fulfilled automatically thanks to the accompanying "in-process" documentation. We call this principle "compliance in process".

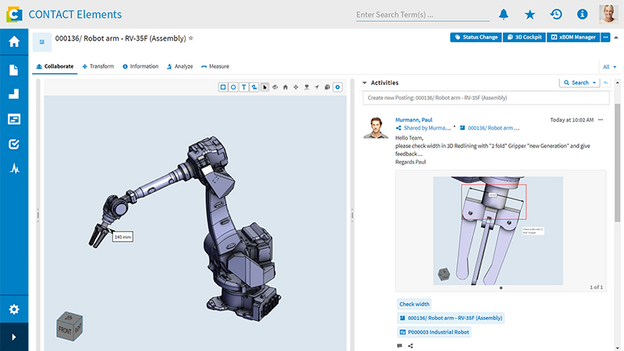

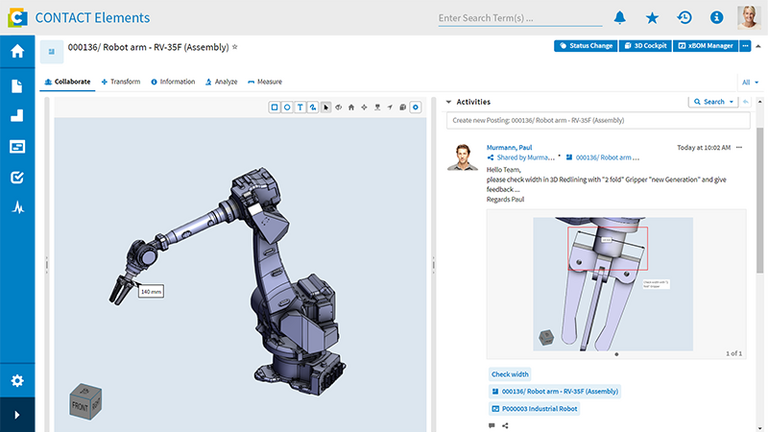

Validate the evaluation of technical changes on the basis of 3D models

Reliably control your test and release processes

Technical changes can often best be evaluated on the basis of the model geometry. With CONTACT 3D Connect, you can give your staff this possibility and thus validate the evaluation of the change. 3D Connect makes the 3D models and information available on every workstation without the need for a CAD system or separate viewer. Redlining and markups are easy to perform and can be shared directly with colleagues. In this way, you can reliably control your change, assessment and approval processes together with information from the product structure and document base.

Validate the evaluation of technical changes on the basis of 3D models

Reliably control your test and release processes

Technical changes can often best be evaluated on the basis of the model geometry. With CONTACT 3D Connect, you can give your staff this possibility and thus validate the evaluation of the change. 3D Connect makes the 3D models and information available on every workstation without the need for a CAD system or separate viewer. Redlining and markups are easy to perform and can be shared directly with colleagues. In this way, you can reliably control your change, assessment and approval processes together with information from the product structure and document base.

Reliably control your test and release processes

Technical changes can often best be evaluated on the basis of the model geometry. With CONTACT 3D Connect, you can give your staff this possibility and thus validate the evaluation of the change. 3D Connect makes the 3D models and information available on every workstation without the need for a CAD system or separate viewer. Redlining and markups are easy to perform and can be shared directly with colleagues. In this way, you can reliably control your change, assessment and approval processes together with information from the product structure and document base.

Secure planning of technical changes, faster implementation and comprehensible documentation

Engineering changes constitute one of the major processes in the life cycle of a product. Their impact on quality, costs and time-to-market require concise planning, execution and documentation. CIM Database‘s digital, workflow-driven Engineering Change Management system provides manufacturers with a powerful alternative to a traditionally manual, paper-based approach. Well defined order structures with all related parts, documents and models, together with the process control, provide the backbone for a targeted, digital engineering change procedure.

Related Elements

Manage tasks, standardize and accelerate processes and meet regulatory requirements

Map and standardize recurring processes as process templates

Speed up processes and ensure compliance

Direct integration in task and project management

Ensure the compliance of materials during the development process

Ensure transparency of materials used in products

Make sure that only permitted materials are processed

Quality-tested delivery of regulated materials

Be better informed and make faster decisions with 3D product data

Better processes with model data at the push of a button

Visual analyses and decisions with the 3D Cockpit

Easier sharing of model data for team collaboration

3D-PDF, JT & STEP: More possibilities with standards

Digital mockups accelerate product protection

Faster, more reliable availability of project, product and customer documentation

Integrated project and document management and best practices for documentation

In-process documentation avoids time-consuming subsequent rework

Automatically generate documentation of deliverables

Use DMU models to validate products early, fast and cost-effectively

High-end DMU functions at every workstation

Validate technical changes with automated geometry comparisons

Collision calculations for optimal decisions on variant-specific geometry

High-quality image data for documentation or marketing directly from CAD models

Manage parts company-wide and ensure material conformity

Avoid costs and liability risks with company-wide controlled parts inventory

Efficiently manage the parts inventory with digital processes

Find parts faster and improve reuse

Ensure material conformity with regulations such as REACH and RoHS

Further information

Would you like to find out more about this topic? Choose one of the following information offers.