Improving the interaction between development and simulation

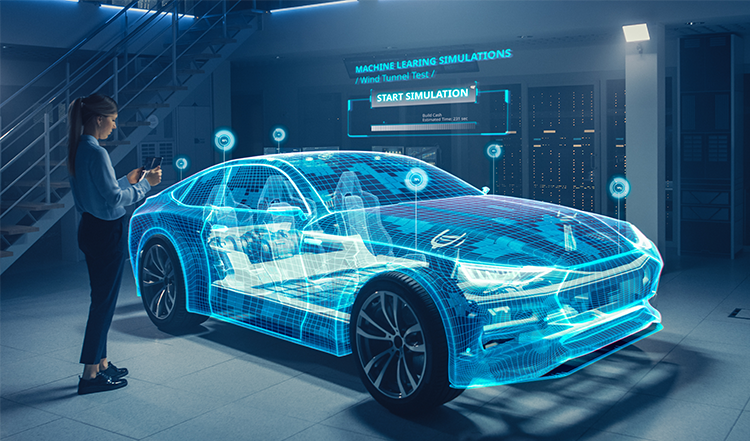

components, avoid costly prototypes, or shorten development cycles. This increases the challenge of making simulation data available company-wide and integrating it into product development. However, this data is often managed in isolation. This leads to problems like a lack of traceability, inefficient collaboration, and competitive disadvantages in terms of quality, time, and cost. Establish integrated data and process management with CONTACT Elements Simulation Management! Learn how to improve the interaction of disciplines, ensure the availability of consistent simulation data, and leverage automation potential.

Benefits of Simulation Management

- Make simulation methods available company-wide

- Accelerate development and simulation processes through automation

- Efficiently integrate CAD and CAE to reduce effort and errors

- Clearly assign relationships with consistent data management

- Standardize workflows and manage tasks in an agile way

- Test the benefits with a Proof of Concept

Enable company-wide access to simulations

Simulations are indispensable for concept evaluation, function design, and product optimization. They replace testing with expensive prototypes by calculating properties. This accelerates the optimization of important product characteristics such as performance, weight, or consumption. With CONTACT Elements Simulation Management, you can utilize this potential throughout your company. The keys to this are clear data organization and ease of use, including predefined templates. Even occasional users have access to proven methods – including complex calculations.

Enable company-wide access to simulations

Simulations are indispensable for concept evaluation, function design, and product optimization. They replace testing with expensive prototypes by calculating properties. This accelerates the optimization of important product characteristics such as performance, weight, or consumption. With CONTACT Elements Simulation Management, you can utilize this potential throughout your company. The keys to this are clear data organization and ease of use, including predefined templates. Even occasional users have access to proven methods – including complex calculations.

Simulations are indispensable for concept evaluation, function design, and product optimization. They replace testing with expensive prototypes by calculating properties. This accelerates the optimization of important product characteristics such as performance, weight, or consumption. With CONTACT Elements Simulation Management, you can utilize this potential throughout your company. The keys to this are clear data organization and ease of use, including predefined templates. Even occasional users have access to proven methods – including complex calculations.

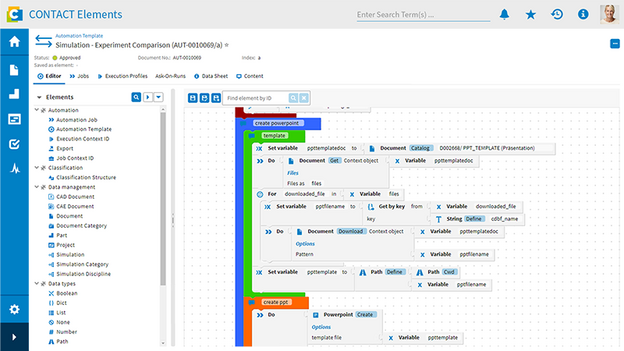

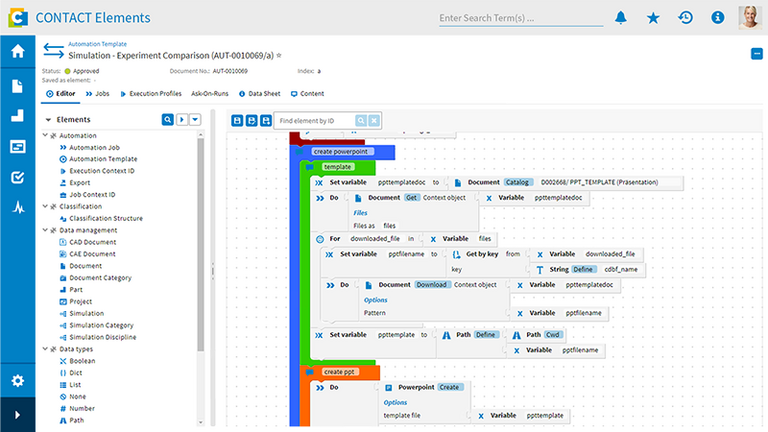

Automate processes with ease

Simulation Management allows you to automate CAE processes. With the integrated Visual Code Editor, your CAE engineers develop state-of-the-art mini apps that are provided as templates in a central library. CAE tools like Abaqus, CarMaker, or Adams are seamlessly integrated. Your CAD engineers can carry out calculations for models themselves. This allows you to quickly and easily put automated calculation processes into productive use. You accelerate both development and simulation processes.

Automate processes with ease

Simulation Management allows you to automate CAE processes. With the integrated Visual Code Editor, your CAE engineers develop state-of-the-art mini apps that are provided as templates in a central library. CAE tools like Abaqus, CarMaker, or Adams are seamlessly integrated. Your CAD engineers can carry out calculations for models themselves. This allows you to quickly and easily put automated calculation processes into productive use. You accelerate both development and simulation processes.

Simulation Management allows you to automate CAE processes. With the integrated Visual Code Editor, your CAE engineers develop state-of-the-art mini apps that are provided as templates in a central library. CAE tools like Abaqus, CarMaker, or Adams are seamlessly integrated. Your CAD engineers can carry out calculations for models themselves. This allows you to quickly and easily put automated calculation processes into productive use. You accelerate both development and simulation processes.

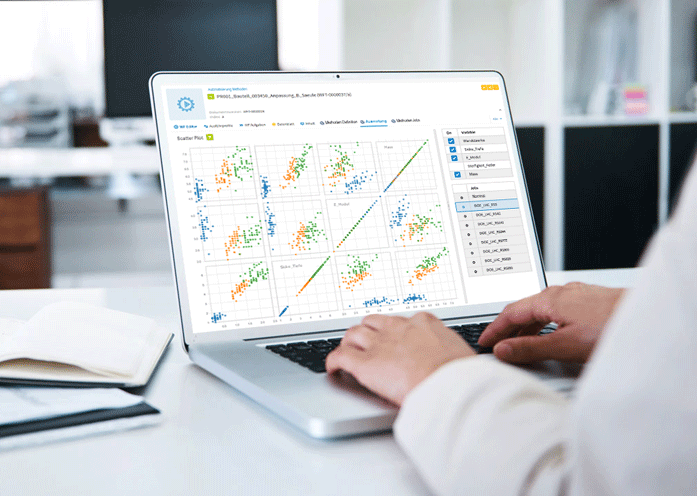

Connect CAD and CAE efficiently

Manual work steps in the interaction between design, validation, and optimization are time-consuming, especially with frequent simulation runs. There is also an increased risk of errors. Integrated data management provides a remedy here: it clearly assigns data, creates contexts, and automates tasks like searching for current CAD versions or data preparation. Documentation also becomes easier: all process steps, versions, and parameter variants are automatically recorded and documented in a traceable manner.

Connect CAD and CAE efficiently

Manual work steps in the interaction between design, validation, and optimization are time-consuming, especially with frequent simulation runs. There is also an increased risk of errors. Integrated data management provides a remedy here: it clearly assigns data, creates contexts, and automates tasks like searching for current CAD versions or data preparation. Documentation also becomes easier: all process steps, versions, and parameter variants are automatically recorded and documented in a traceable manner.

Manual work steps in the interaction between design, validation, and optimization are time-consuming, especially with frequent simulation runs. There is also an increased risk of errors. Integrated data management provides a remedy here: it clearly assigns data, creates contexts, and automates tasks like searching for current CAD versions or data preparation. Documentation also becomes easier: all process steps, versions, and parameter variants are automatically recorded and documented in a traceable manner.

Standardize workflows and manage tasks with agility

Managing simulation tasks requires significant organizational effort. With the CONTACT Elements Workflow Designer, you standardize recurring processes digitally. Individual simulation jobs can be recorded, assigned and tracked as tasks or open points together with the associated data. Task boards support self-organized teamwork and provide an overview of current simulations at all times - ideal for agile project environments.

Standardize workflows and manage tasks with agility

Managing simulation tasks requires significant organizational effort. With the CONTACT Elements Workflow Designer, you standardize recurring processes digitally. Individual simulation jobs can be recorded, assigned and tracked as tasks or open points together with the associated data. Task boards support self-organized teamwork and provide an overview of current simulations at all times - ideal for agile project environments.

Managing simulation tasks requires significant organizational effort. With the CONTACT Elements Workflow Designer, you standardize recurring processes digitally. Individual simulation jobs can be recorded, assigned and tracked as tasks or open points together with the associated data. Task boards support self-organized teamwork and provide an overview of current simulations at all times - ideal for agile project environments.

Evaluate the benefits of simulation with a Proof of Concept

Convince yourself of the benefits of an integrated simulation management solution - practical, risk-free and at an attractive fixed price! With a customized Proof of Concept, you can test how your requirements can be optimally supported.

Evaluate the benefits of simulation with a Proof of Concept

Convince yourself of the benefits of an integrated simulation management solution - practical, risk-free and at an attractive fixed price! With a customized Proof of Concept, you can test how your requirements can be optimally supported.

Convince yourself of the benefits of an integrated simulation management solution - practical, risk-free and at an attractive fixed price! With a customized Proof of Concept, you can test how your requirements can be optimally supported.

Related Elements

Manage CAx data across different disciplines and locations

Consolidate and manage CAx data across disciplines

Optimally support product development

Smoothly exchange design data with partners and customers

Create product structures and architectures accurately

Develop products that meet requirements

Create mechatronic product structures for systems engineering

Configure variants with 150% structures

Manage parts lists and ensure compliance

Use reliable interfaces between development and production

From virtual product to smooth start of production

Create transparency in the pre-series process

Map series startup process robustly and control it cost-effectively

Schedule prototype BOMs precisely and on time

Document activities in prototyping and testing and synchronize tools with production

Get better insights and make faster decisions with 3D product data

Design processes at the push of a button with model data

Use visual analyses and make decisions with the 3D cockpit

Enhance team collaboration by sharing model data

Leverage standards like 3D PDF, JT, and STEP for more possibilities

Accelerate product protection with digital mockups

Validate products earlier, faster and more cost-effectively

Provide DMU functions at every workstation

Validate technical changes with automated geometry comparisons

Calculate collisions for optimal decisions on variant-specific geometry

High-quality image data for documentation or marketing directly from CAD models

Further information

Would you like to find out more about this topic? Choose one of the following information offers.