Press release – April 12, 2024

CONTACT Software presents new solutions for sustainable production processes

In its presentations at Hannover Messe, CONTACT Software demonstrates how companies utilize the digital twin, Artificial Intelligence, and simulations to make their manufacturing processes more energy-efficient.

Energy efficiency is a crucial lever for the manufacturing industry to address high electricity costs, stringent environmental regulations, and the growing sustainability awareness among customers. On Hannover Messe’s conference stages, CONTACT Software shows how companies can reduce energy consumption in production sustainably and combine climate protection with competitiveness.

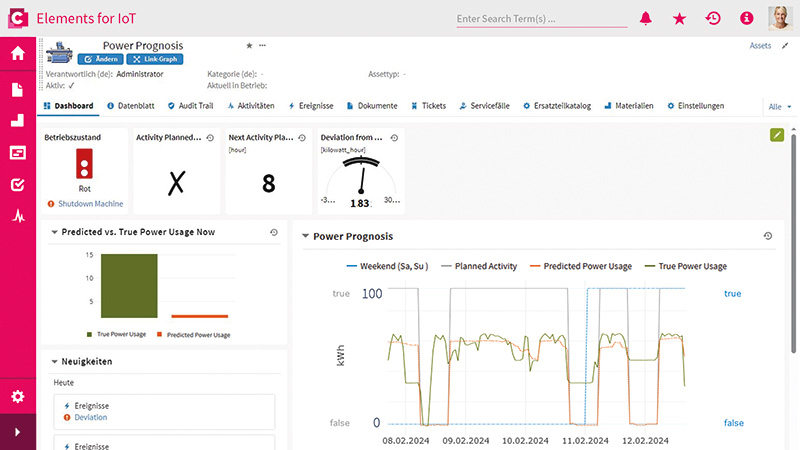

Dr. Nicole Göckel starts things off with her presentation AI-based Prognosis for the Energy Demand: Optimization Approaches in the Shopfloor on the Energy 4.0 Conference Stage (April 23, 2:40 pm, hall 12, booth D35). In her talk, she illuminates how energy consumption in manufacturing can be reduced through AI-based forecasts in CONTACT Elements for IoT.

CONTACT's IoT platform uses the digital twin of a machine to capture its energy consumption. If the software detects deviations between the pre-calculated target and actual values, it notifies production managers via a dashboard. This allows them to quickly initiate appropriate countermeasures.

Using the practical example of a grinding machine, the presentation illustrates how electricity costs are reduced by efficient shutdowns that take into account planned production orders and ramp-up times. Additionally, production orders can be planned based on their consumption forecasts to avoid expensive peak loads.

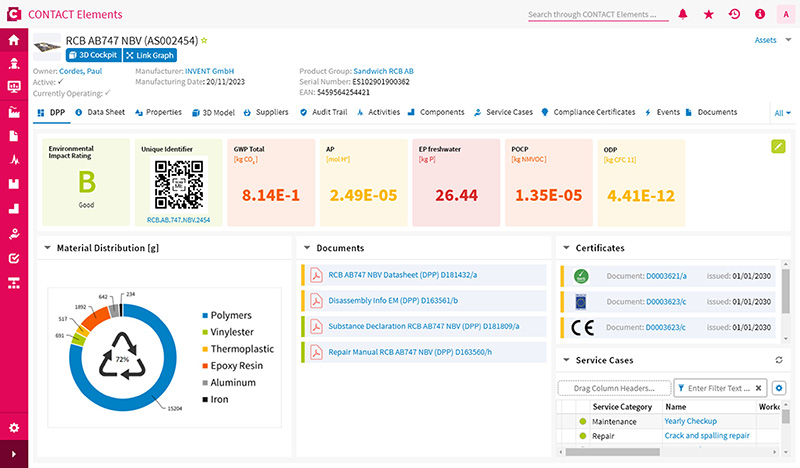

In their presentation PredictECO – Development of a Virtual Production Twin for Sustainability Assessment on the Tech Transfer Conference Stage (April 24, 9:35 am, hall 2, booth B02), Maximilian Idjen from CONTACT Research and Dr. Oliver Lohse from Siemens introduce a joint project in the aerospace industry. At its core is a green digital twin that stores environmental information and serves as a virtual representation of production. The project aims to establish sustainability as a key factor in product development in order to use resources more efficiently and meet national and EU-wide climate protection goals.

Using manufacturing simulations and intelligent analyses, the sustainability of production processes can already be assessed in the design phase. The results of PredictECO are being validated in the energy-intensive manufacturing of fiber composite. The prototype solution enables the evaluation of sustainability KPIs, which can be used to optimize manufacturing and make sustainable decisions.

The presentations will be streamed live. CONTACT presents the entire solution portfolio for PLM, IoT, and MES of its open low-code platform CONTACT Elements at its main booth H24 in hall 17. Here, visitors can also discover use cases for the Asset Administration Shell (AAS) together with Mitsubishi Electric, as well as with msg at the IDTA stand (hall 9, booth F27). CONTACT will also be present at the OWL joint booth D27 in hall 07 and the Fujitsu booth H62 in hall 14.