Reduce product data complexity through classification

In the product and manufacturing environment, structured management of complex product data is a key success factor. Without it, the consequences can be severe: lack of data transparency hinders reuse, the number of parts grows uncontrollably, and efforts in design as well as storage and procurement costs increase. With CONTACT Elements Universal Classification, you ensure transparent data organization by classifying all data objects. Discover how to accelerate the search for parts, documents, and other information ‒ laying the foundation for automated processes and strategic analysis.

Benefits of Universal Classification

- Organize master data transparently and systematically using classification systems

- Visually support and accelerate the search for objects such as parts and documents

- Reduce costs through reuse and decreased part diversity

- Provide tailored views for engineering, procurement, and sales

- Drive standardization while supporting compliance and sustainability

Create transparency in the data inventory

Universal Classification provides the technological foundation to organize and structure all data objects based on classes and attributes. Whether it's items, documents, requirements, materials, or assets – classification according to portfolio-relevant attributes creates full transparency in the product data inventory and enables well-informed decision-making. It speeds up the search for objects such as items and reduces costs by avoiding duplicates and increasing reuse.

Universal Classification provides the technological foundation to organize and structure all data objects based on classes and attributes. Whether it's items, documents, requirements, materials, or assets – classification according to portfolio-relevant attributes creates full transparency in the product data inventory and enables well-informed decision-making. It speeds up the search for objects such as items and reduces costs by avoiding duplicates and increasing reuse.

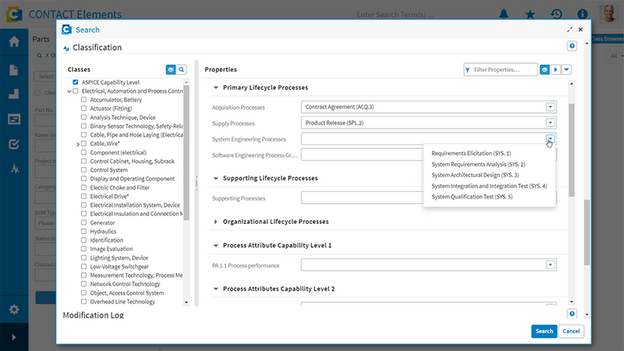

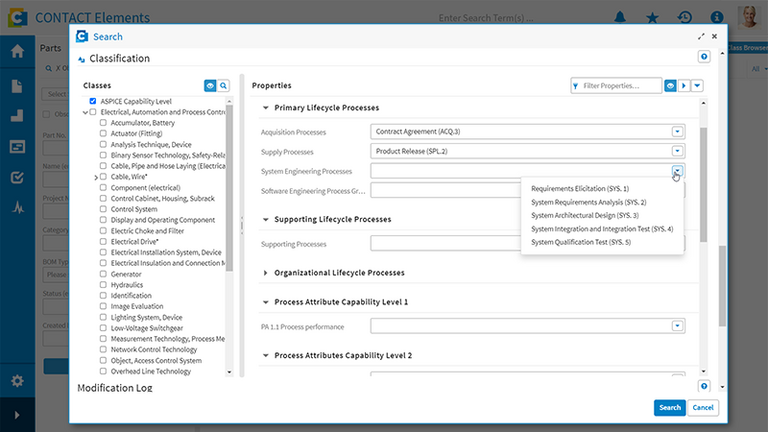

Set up a class system efficiently and flexibly

With Universal Classification, you can design your classification structure as flexibly as your portfolio requires. Through an intuitive user interface, you create new classes, define attributes, and structure your classification system according to your needs. Attributes can be defined using data types such as text, numbers, or Boolean values and used for classification. This allows you to accurately represent your product and process data. Frequently used attributes can be predefined in a catalog and inherited within the class hierarchy.

Set up a class system efficiently and flexibly

With Universal Classification, you can design your classification structure as flexibly as your portfolio requires. Through an intuitive user interface, you create new classes, define attributes, and structure your classification system according to your needs. Attributes can be defined using data types such as text, numbers, or Boolean values and used for classification. This allows you to accurately represent your product and process data. Frequently used attributes can be predefined in a catalog and inherited within the class hierarchy.

With Universal Classification, you can design your classification structure as flexibly as your portfolio requires. Through an intuitive user interface, you create new classes, define attributes, and structure your classification system according to your needs. Attributes can be defined using data types such as text, numbers, or Boolean values and used for classification. This allows you to accurately represent your product and process data. Frequently used attributes can be predefined in a catalog and inherited within the class hierarchy.

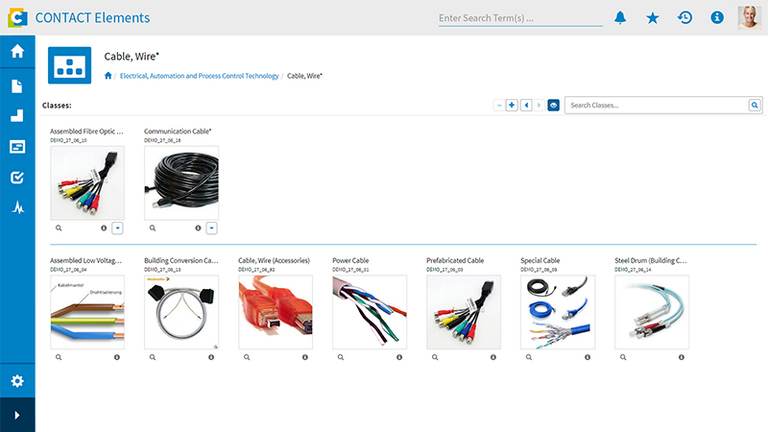

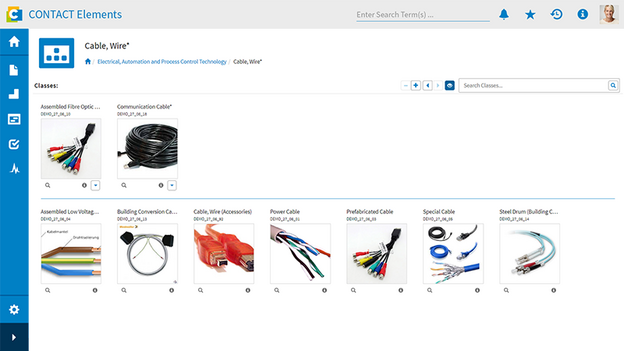

Find parts faster with visual search

The Class Browser allows you to intuitively navigate through your parts inventory, making it significantly easier to identify required components. Classification data is presented visually, which further simplifies the search for parts in combination with traditional search and filter functions.

Find parts faster with visual search

The Class Browser allows you to intuitively navigate through your parts inventory, making it significantly easier to identify required components. Classification data is presented visually, which further simplifies the search for parts in combination with traditional search and filter functions.

The Class Browser allows you to intuitively navigate through your parts inventory, making it significantly easier to identify required components. Classification data is presented visually, which further simplifies the search for parts in combination with traditional search and filter functions.

Mapping different views with multiple classification

Multi-classification effectively supports flexible views: Attributes from areas such as engineering, procurement, or sales can be managed independently on the same object. This allows you to easily meet the specific view requirements of each department. While engineering primarily focuses on technical and functional attributes, procurement and sales are more concerned with pricing or supplier-related information. By representing these different requirements, you provide each department with the information they need.

Mapping different views with multiple classification

Multi-classification effectively supports flexible views: Attributes from areas such as engineering, procurement, or sales can be managed independently on the same object. This allows you to easily meet the specific view requirements of each department. While engineering primarily focuses on technical and functional attributes, procurement and sales are more concerned with pricing or supplier-related information. By representing these different requirements, you provide each department with the information they need.

Multi-classification effectively supports flexible views: Attributes from areas such as engineering, procurement, or sales can be managed independently on the same object. This allows you to easily meet the specific view requirements of each department. While engineering primarily focuses on technical and functional attributes, procurement and sales are more concerned with pricing or supplier-related information. By representing these different requirements, you provide each department with the information they need.

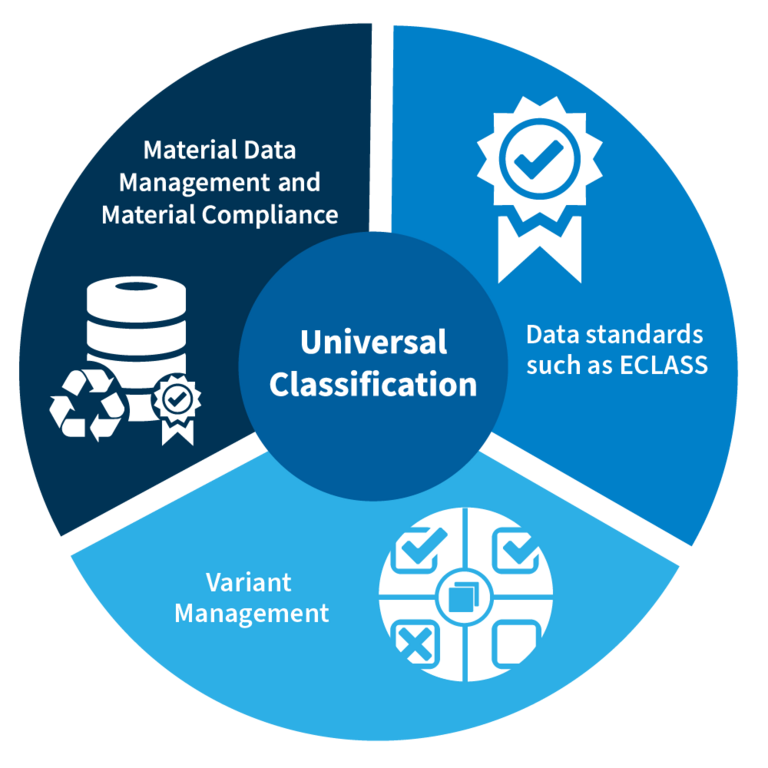

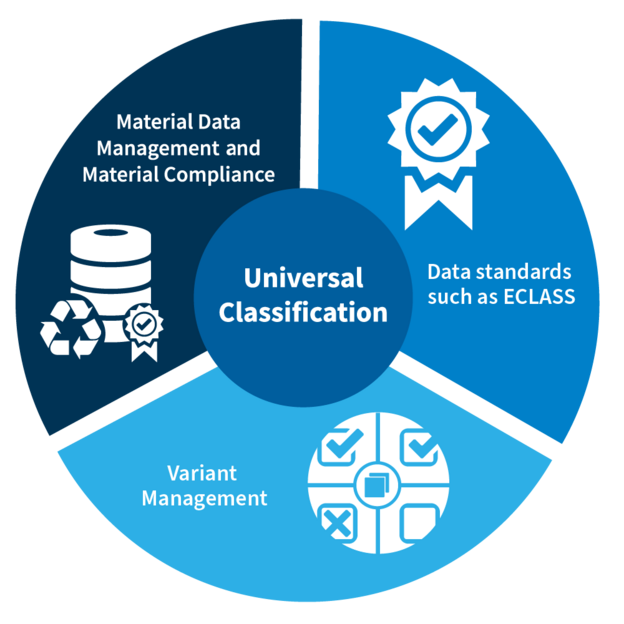

Support applications and standards

The combination of Universal Classification and other CONTACT Elements modules allows you to meet regulatory requirements easily and reliably. In conjunction with Material Data Management and Material Compliance, for example, you can manage materials and ensure that they comply with relevant norms and standards. Variant Management is also based on Universal Classification: defined product variants are automatically classified. Additional attribute-based classifications can be implemented without difficulty. Represent data standards such as ECLASS and use standardization as a foundation for automating your processes.

Support applications and standards

The combination of Universal Classification and other CONTACT Elements modules allows you to meet regulatory requirements easily and reliably. In conjunction with Material Data Management and Material Compliance, for example, you can manage materials and ensure that they comply with relevant norms and standards. Variant Management is also based on Universal Classification: defined product variants are automatically classified. Additional attribute-based classifications can be implemented without difficulty. Represent data standards such as ECLASS and use standardization as a foundation for automating your processes.

The combination of Universal Classification and other CONTACT Elements modules allows you to meet regulatory requirements easily and reliably. In conjunction with Material Data Management and Material Compliance, for example, you can manage materials and ensure that they comply with relevant norms and standards. Variant Management is also based on Universal Classification: defined product variants are automatically classified. Additional attribute-based classifications can be implemented without difficulty. Represent data standards such as ECLASS and use standardization as a foundation for automating your processes.

Related Elements

Increase reuse and reduce costs through classification

Accelerate part search

Effectively support the search for geometrically similar parts

Ensure material compliance in the development process

Ensure a transparent view of the materials used in products

Make sure that only permitted materials are processed

Quality-tested delivery of regulated materials

Manage material information company-wide and ensure sustainability

Make detailed material information available across the entire organization

Collaborate seamlessly with reliable material data

Quickly identify alternative materials

Ensure sustainability and compliance

Combine customer orientation with efficient value creation

Build product portfolios efficiently and strategically

Achieve the ideal balance between customer orientation and cost-effectiveness

Modularize product variability and manage it consistently throughout the product lifecycle

Maintain transparency and clarity even in complex variant spaces

Automatically supply downstream processes with data

Further information

Would you like to find out more about this topic? Choose one of the following information offers.