Master your supply chain and sustainability challenges

Rising raw material prices, supply bottlenecks, and growing demands for sustainability and compliance present significant challenges for production planning. To prevent production disruptions, companies must make their supply chains more resilient. At the same time, customers and legislators are demanding improved environmental performance of products. CONTACT Elements Material Data Management is the PLM building block for modern, sustainable material management. The solution helps you manage materials efficiently, flexibly, and in a future-proof way. This enables you to reliably meet new requirements – such as the rapid identification of alternative materials – and establish strategically robust procurement.

Your benefits

- Provide detailed material information company-wide

- Collaborate seamlessly thanks to reliable material data

- Quickly identify alternative materials

- Ensure sustainability and compliance

Provide material information company-wide

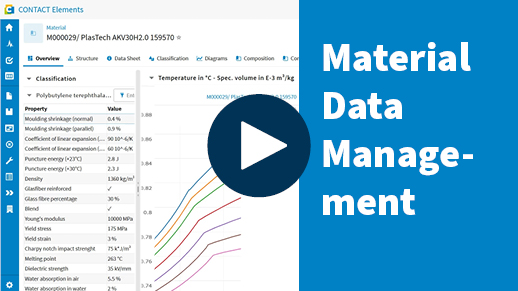

CONTACT’s Material Data Management centralizes all relevant material information: from properties and substances to product composition, analyses, and measurement reports. The integrated material catalog is seamlessly connected to Product Lifecycle Management and Simulation Management. This enables a smooth, cross-departmental exchange of information. Status networks and release workflows ensure consistent material data and traceable design decisions.

Provide material information company-wide

CONTACT’s Material Data Management centralizes all relevant material information: from properties and substances to product composition, analyses, and measurement reports. The integrated material catalog is seamlessly connected to Product Lifecycle Management and Simulation Management. This enables a smooth, cross-departmental exchange of information. Status networks and release workflows ensure consistent material data and traceable design decisions.

CONTACT’s Material Data Management centralizes all relevant material information: from properties and substances to product composition, analyses, and measurement reports. The integrated material catalog is seamlessly connected to Product Lifecycle Management and Simulation Management. This enables a smooth, cross-departmental exchange of information. Status networks and release workflows ensure consistent material data and traceable design decisions.

Collaborate seamlessly thanks to reliable material data

Material Data Management provides all relevant departments with direct access to qualified and released material data. This allows design department to precisely weigh properties during material selection, procurement to assess availability and prices, simulation to test product requirements such as elasticity, and quality assurance to evaluate the data regarding sustainability and compliance. This company-wide access to consistent data promotes highly efficient cross-team collaboration.

Collaborate seamlessly thanks to reliable material data

Material Data Management provides all relevant departments with direct access to qualified and released material data. This allows design department to precisely weigh properties during material selection, procurement to assess availability and prices, simulation to test product requirements such as elasticity, and quality assurance to evaluate the data regarding sustainability and compliance. This company-wide access to consistent data promotes highly efficient cross-team collaboration.

Material Data Management provides all relevant departments with direct access to qualified and released material data. This allows design department to precisely weigh properties during material selection, procurement to assess availability and prices, simulation to test product requirements such as elasticity, and quality assurance to evaluate the data regarding sustainability and compliance. This company-wide access to consistent data promotes highly efficient cross-team collaboration.

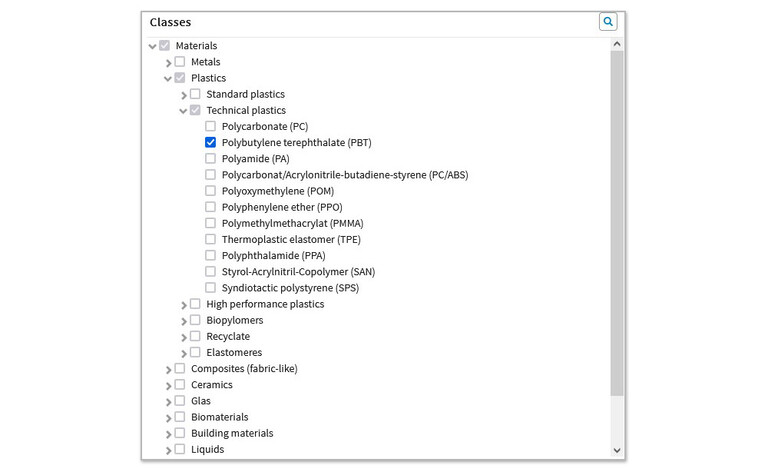

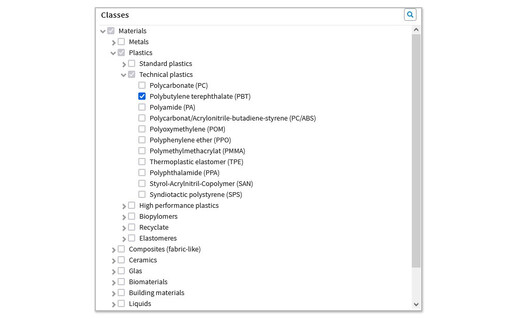

Quickly identify alternative materials

In view of disrupted supply chains, rising raw material prices, and growing sustainability requirements, the rapid identification of alternative materials is crucial. CONTACT’s Material Data Management significantly simplifies and accelerates this search: Employees can filter by attributes such as manufacturer, supplier, substances, material properties, or material classes (for example, metal or plastic). The comprehensive classification and detailed mapping of material information drastically speeds up the search for suitable alternatives.

Quickly identify alternative materials

In view of disrupted supply chains, rising raw material prices, and growing sustainability requirements, the rapid identification of alternative materials is crucial. CONTACT’s Material Data Management significantly simplifies and accelerates this search: Employees can filter by attributes such as manufacturer, supplier, substances, material properties, or material classes (for example, metal or plastic). The comprehensive classification and detailed mapping of material information drastically speeds up the search for suitable alternatives.

In view of disrupted supply chains, rising raw material prices, and growing sustainability requirements, the rapid identification of alternative materials is crucial. CONTACT’s Material Data Management significantly simplifies and accelerates this search: Employees can filter by attributes such as manufacturer, supplier, substances, material properties, or material classes (for example, metal or plastic). The comprehensive classification and detailed mapping of material information drastically speeds up the search for suitable alternatives.

Ensure sustainability and compliance

An integrated material management system is essential for sustainable product development and compliance with product regulations. With CONTACT Elements Material Data Management, companies can easily fulfill requirements such as substance declarations and the declaration of materials used. Furthermore, sustainability information can be comprehensively mapped in digital product files. This enables its use for environmentally sound product design (Design for Environment, DfE) and the creation of life cycle assessments, thereby paving the way for future-proof production.

Ensure sustainability and compliance

An integrated material management system is essential for sustainable product development and compliance with product regulations. With CONTACT Elements Material Data Management, companies can easily fulfill requirements such as substance declarations and the declaration of materials used. Furthermore, sustainability information can be comprehensively mapped in digital product files. This enables its use for environmentally sound product design (Design for Environment, DfE) and the creation of life cycle assessments, thereby paving the way for future-proof production.

An integrated material management system is essential for sustainable product development and compliance with product regulations. With CONTACT Elements Material Data Management, companies can easily fulfill requirements such as substance declarations and the declaration of materials used. Furthermore, sustainability information can be comprehensively mapped in digital product files. This enables its use for environmentally sound product design (Design for Environment, DfE) and the creation of life cycle assessments, thereby paving the way for future-proof production.

Anchor sustainability in PLM

In the commentary by consulting firm CIMdata, you learn how to document and reduce the environmental impact of your products with CONTACT Elements.

Related Elements

Manage product structures and bills of materials securely and efficiently

Ensure compliance through end-to-end documentation of product development

Efficiently configure variants using 150% bills of materials

Compare product structures and drive standardization

Build product architectures across disciplines

Supply downstream processes with reliable data

Classify and find parts, documents, and other objects faster

Organize master data transparently and systematically using classification systems

Visually support and accelerate the search for objects such as parts and documents

Reduce costs through reuse and decreased part diversity

Provide tailored views for engineering, procurement, and sales

Drive standardization while supporting compliance and sustainability

Plan, implement, and document technical changes

Accelerate change processes through digital workflows and standards

Simplify work with digital folders and Task Manager

Map change processes easily and flexibly and benefit from end-to-end documentation

Validate the analysis of technical changes using 3D models

Ensure material compliance in the development process

Ensure a transparent view of the materials used in products

Make sure that only permitted materials are processed

Quality-tested delivery of regulated materials

Further information

Would you like to find out more about this topic? Choose one of the following information offers.