Improve your products and quickly respond to new requirements

Today, companies benefit more than ever from the combination of Product Lifecycle Management (PLM) and the Industrial Internet of Things (IIoT). By intelligently utilizing operational and usage data, a powerful cycle is created: Products can be continuously optimized, innovations developed more quickly, and new market or customer demands addressed proactively. Discover how CONTACT's Closed Loop Engineering can future-proof your product development and significantly boost your competitiveness. Modern, data-driven methods help you respond more agilely to customer needs, meet sustainability targets, and strengthen your innovation capability.

Your benefits

- Combine PLM and IoT into an innovative closed-loop process

- Strategically improve products based on operational and usage data

- Incorporate field data, tickets, and classification into development

- Efficiently implement and seamlessly document technical changes

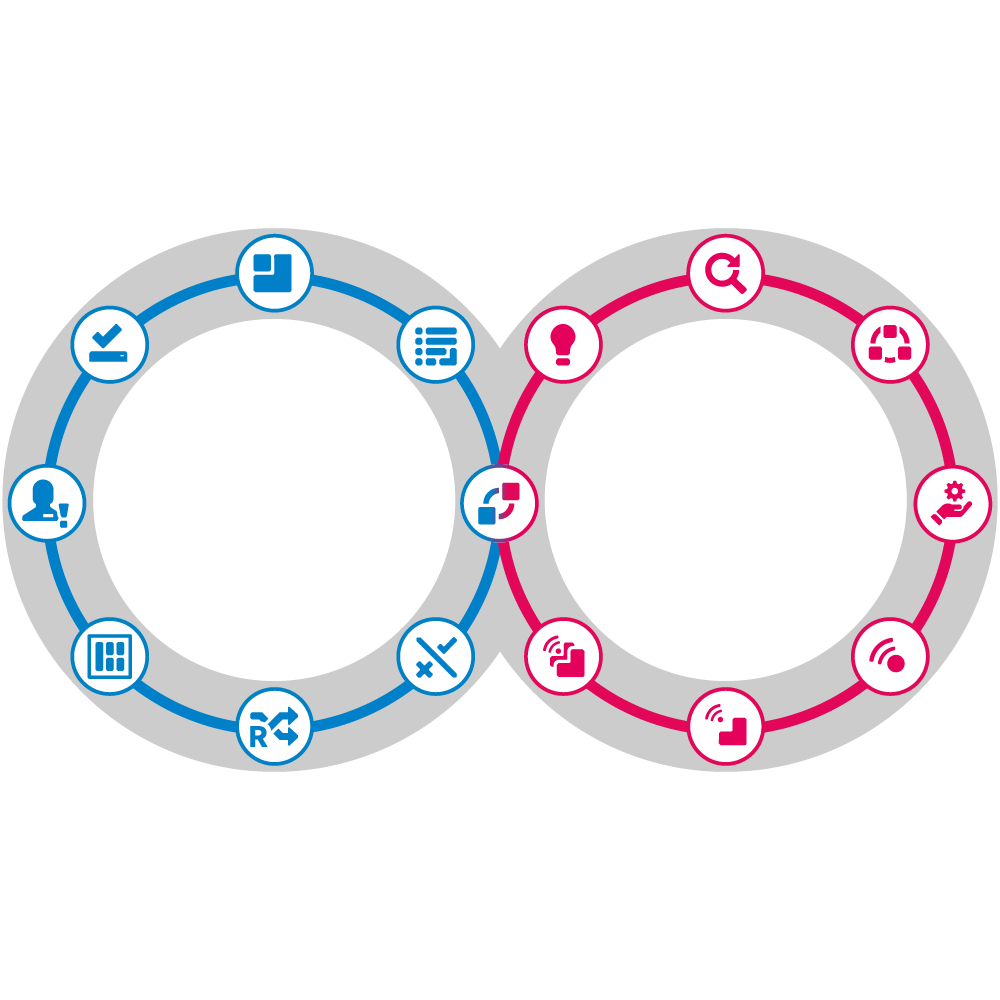

Combine PLM and IoT into an innovative closed-loop process

Closed Loop Engineering ushers in a new era of product development: Create an innovative feedback process that feeds data from your manufacturing, along with operational and usage data from the field, back into your development. This intelligent connection of PLM and IoT enables you to develop, produce, and operate products more efficiently and sustainably than ever before. Automating processes that span from development across the shop floor to service and logistics ensure greater transparency and boost the efficiency of your value chain.

Combine PLM and IoT into an innovative closed-loop process

Closed Loop Engineering ushers in a new era of product development: Create an innovative feedback process that feeds data from your manufacturing, along with operational and usage data from the field, back into your development. This intelligent connection of PLM and IoT enables you to develop, produce, and operate products more efficiently and sustainably than ever before. Automating processes that span from development across the shop floor to service and logistics ensure greater transparency and boost the efficiency of your value chain.

Closed Loop Engineering ushers in a new era of product development: Create an innovative feedback process that feeds data from your manufacturing, along with operational and usage data from the field, back into your development. This intelligent connection of PLM and IoT enables you to develop, produce, and operate products more efficiently and sustainably than ever before. Automating processes that span from development across the shop floor to service and logistics ensure greater transparency and boost the efficiency of your value chain.

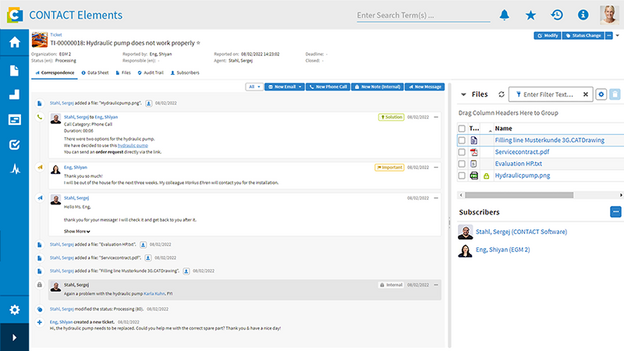

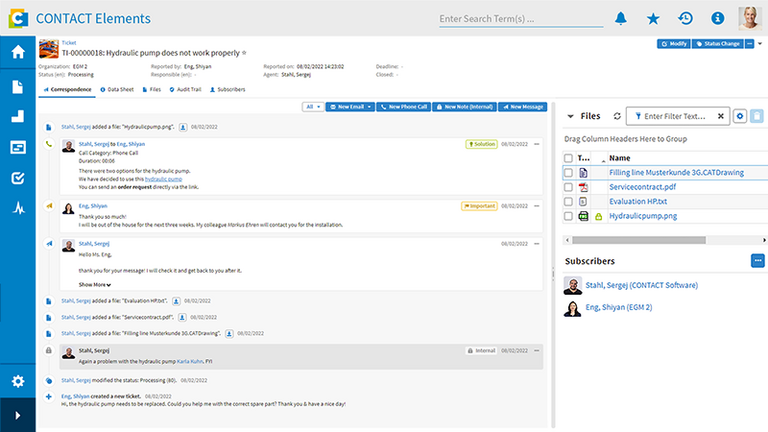

Incorporate information into development with tickets and classification

CONTACT Elements optimizes information flow with its proven ticket system. Centrally capture and organize operational and usage data as well as customer concerns. This allows you to precisely route relevant information to the responsible development teams or individuals. Digital workflows ensure transparency and seamless documentation at every processing step. Additionally, CONTACT Elements Universal Classification enables intelligent structuring of product-related data – whether by technical requirements, new features, or material variants.

Incorporate information into development with tickets and classification

CONTACT Elements optimizes information flow with its proven ticket system. Centrally capture and organize operational and usage data as well as customer concerns. This allows you to precisely route relevant information to the responsible development teams or individuals. Digital workflows ensure transparency and seamless documentation at every processing step. Additionally, CONTACT Elements Universal Classification enables intelligent structuring of product-related data – whether by technical requirements, new features, or material variants.

CONTACT Elements optimizes information flow with its proven ticket system. Centrally capture and organize operational and usage data as well as customer concerns. This allows you to precisely route relevant information to the responsible development teams or individuals. Digital workflows ensure transparency and seamless documentation at every processing step. Additionally, CONTACT Elements Universal Classification enables intelligent structuring of product-related data – whether by technical requirements, new features, or material variants.

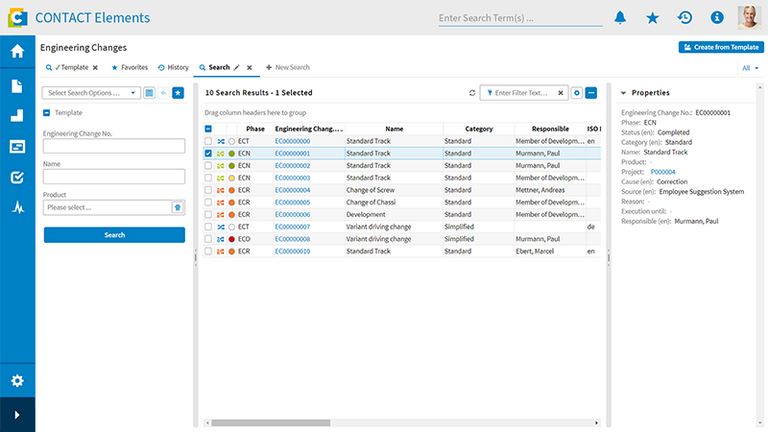

Efficiently implement and seamlessly document technical changes

With CONTACT Elements' Engineering Change Management, you significantly accelerate the implementation of technical changes. Digital workflows and customizable templates simplify the modeling of your change processes and ensure automatic, traceable documentation. You can manage changes to the order-neutral Digital Master and the specific Digital Twin separately, but always synchronized. Thus, thanks to the Closed-Loop methodology, new requirements from the field are not only precisely incorporated into product improvement, but they are also audit-proof documented in the product's lifecycle record.

Efficiently implement and seamlessly document technical changes

With CONTACT Elements' Engineering Change Management, you significantly accelerate the implementation of technical changes. Digital workflows and customizable templates simplify the modeling of your change processes and ensure automatic, traceable documentation. You can manage changes to the order-neutral Digital Master and the specific Digital Twin separately, but always synchronized. Thus, thanks to the Closed-Loop methodology, new requirements from the field are not only precisely incorporated into product improvement, but they are also audit-proof documented in the product's lifecycle record.

With CONTACT Elements' Engineering Change Management, you significantly accelerate the implementation of technical changes. Digital workflows and customizable templates simplify the modeling of your change processes and ensure automatic, traceable documentation. You can manage changes to the order-neutral Digital Master and the specific Digital Twin separately, but always synchronized. Thus, thanks to the Closed-Loop methodology, new requirements from the field are not only precisely incorporated into product improvement, but they are also audit-proof documented in the product's lifecycle record.

Related Elements

Plan, implement, and document technical changes

Accelerate change processes through digital workflows and standards

Simplify work with digital folders and Task Manager

Map change processes easily and flexibly and benefit from end-to-end documentation

Validate the analysis of technical changes using 3D models

Classify and find objects faster

Organize master data transparently and systematically using classification systems

Visually support and accelerate the search for objects such as parts and documents

Reduce costs through reuse and decreased part diversity

Provide tailored views for engineering, procurement, and sales

Drive standardization while supporting compliance and sustainability

Record and resolve complaints and defects

Increase customer satisfaction and reduce series startup costs

Implement seamless processes from error detection to solution archiving

Condition monitoring and predictive maintenance

Automate condition monitoring with IoT data

Offer additional services with predictive maintenance

Analyze fleets and environments

Further information

Would you like to find out more about this topic? Choose one of the following information offers.