Advance the digitalization of product development – with consistently available DMU functionalities

To avoid defective products, functional deficiencies, and safety risks, companies must increasingly replace physical prototypes with Digital Mock-ups (DMU). In practice, however, specialized DMU tools or CAD applications are often used in isolation – by a few experts and without integration into central data management. This prevents end-to-end digital processes and significantly limits the use of DMU functionalities. With CONTACT Elements DMU, you can make Digital Mock-ups accessible throughout the entire company – quickly, in an integrated way, and at every workstation.

Your benefits

- Make high-end DMU functionalities available at every workstation

- Reliably evaluate technical changes with automated geometry comparisons

- Utilize collision calculations for informed decisions on geometry variants

- Generate high-quality image data directly from CAD models

Make DMU functionalities available at every workstation

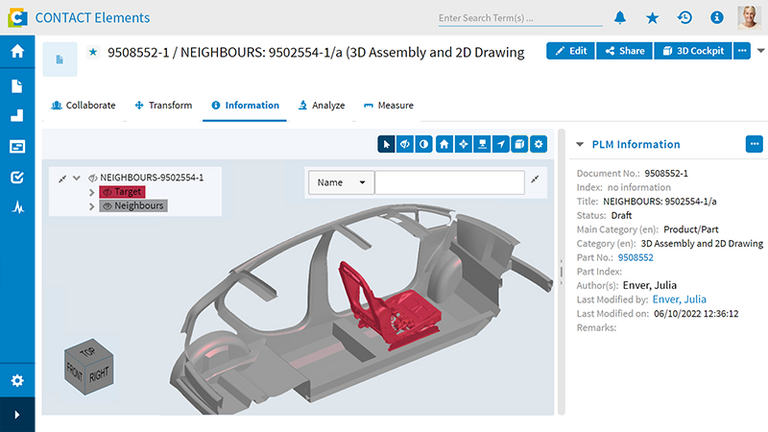

CONTACT Elements DMU is powered by invenio Virtual Technologies, the leading DMU specialist. Thanks to its integration into CONTACT Elements, high-end DMU functionalities for model data from all common CAD systems are immediately available at every workstation within the product development process. Whether for technical changes, variant management, documentation, or marketing – all DMU-relevant information is seamlessly accessible, automated, and available without cumbersome context switching. This enables end-to-end digital processes with maximum efficiency.

Make DMU functionalities available at every workstation

CONTACT Elements DMU is powered by invenio Virtual Technologies, the leading DMU specialist. Thanks to its integration into CONTACT Elements, high-end DMU functionalities for model data from all common CAD systems are immediately available at every workstation within the product development process. Whether for technical changes, variant management, documentation, or marketing – all DMU-relevant information is seamlessly accessible, automated, and available without cumbersome context switching. This enables end-to-end digital processes with maximum efficiency.

CONTACT Elements DMU is powered by invenio Virtual Technologies, the leading DMU specialist. Thanks to its integration into CONTACT Elements, high-end DMU functionalities for model data from all common CAD systems are immediately available at every workstation within the product development process. Whether for technical changes, variant management, documentation, or marketing – all DMU-relevant information is seamlessly accessible, automated, and available without cumbersome context switching. This enables end-to-end digital processes with maximum efficiency.

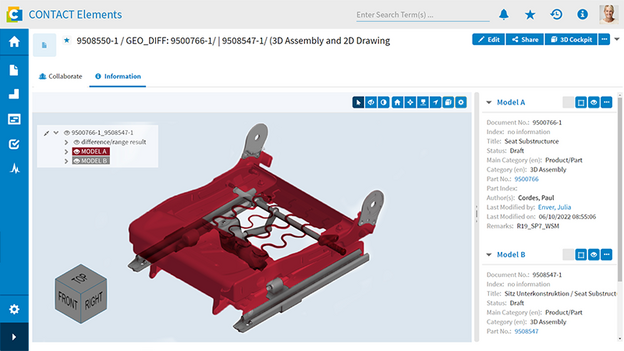

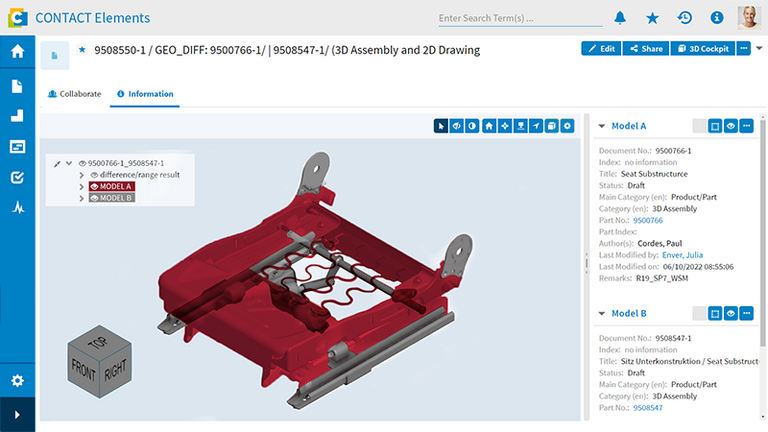

Reliably evaluate technical changes

After a technical change, CONTACT Elements DMU allows you to automatically perform a geometry comparison of the affected parts. The calculation result is documented as a difference model in the change note and dossier. Instead of labor-intensive manual image preparation in Office documents, the result is immediately available as a 3D geometry model for subsequent processes such as quality assurance or manufacturing.

Reliably evaluate technical changes

After a technical change, CONTACT Elements DMU allows you to automatically perform a geometry comparison of the affected parts. The calculation result is documented as a difference model in the change note and dossier. Instead of labor-intensive manual image preparation in Office documents, the result is immediately available as a 3D geometry model for subsequent processes such as quality assurance or manufacturing.

After a technical change, CONTACT Elements DMU allows you to automatically perform a geometry comparison of the affected parts. The calculation result is documented as a difference model in the change note and dossier. Instead of labor-intensive manual image preparation in Office documents, the result is immediately available as a 3D geometry model for subsequent processes such as quality assurance or manufacturing.

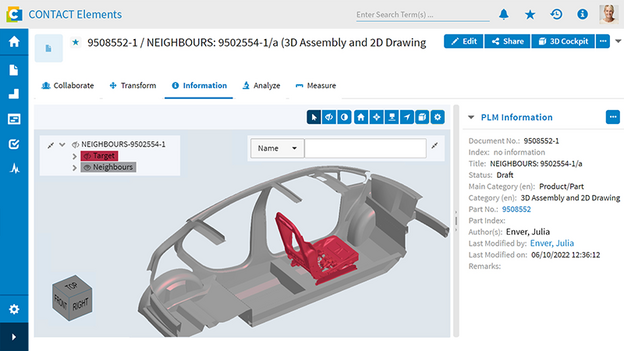

Utilize collision calculations for informed decisions regarding geometry variants

For products with numerous variants, CONTACT Elements DMU supports you with automated collision and clearance calculations (Clash & Clearance). This allows you to check whether changes to product variants are compatible and feasible in all relevant assemblies/configurations. Detected problem areas of individual geometry variants become immediately visible and can be directly resolved. This way, you make informed geometry decisions and gain predictability.

Utilize collision calculations for informed decisions regarding geometry variants

For products with numerous variants, CONTACT Elements DMU supports you with automated collision and clearance calculations (Clash & Clearance). This allows you to check whether changes to product variants are compatible and feasible in all relevant assemblies/configurations. Detected problem areas of individual geometry variants become immediately visible and can be directly resolved. This way, you make informed geometry decisions and gain predictability.

For products with numerous variants, CONTACT Elements DMU supports you with automated collision and clearance calculations (Clash & Clearance). This allows you to check whether changes to product variants are compatible and feasible in all relevant assemblies/configurations. Detected problem areas of individual geometry variants become immediately visible and can be directly resolved. This way, you make informed geometry decisions and gain predictability.

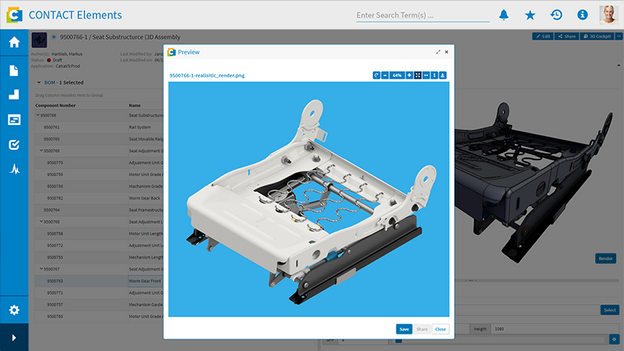

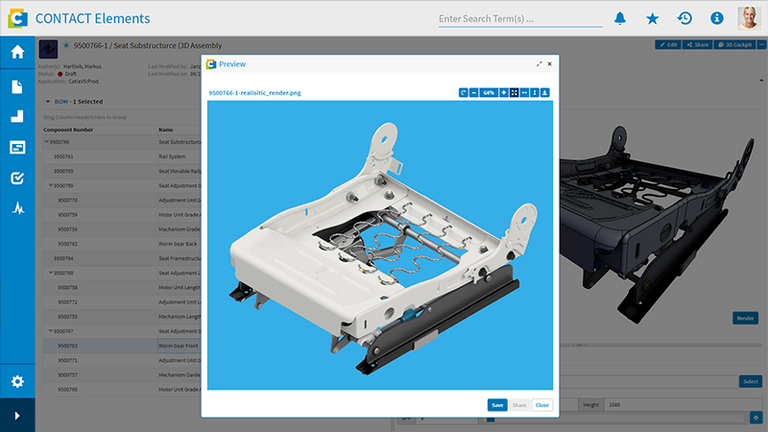

Generate high-quality image data directly from CAD models

Based on existing model data, you automatically generate high-quality image and render data for technical documentation or marketing purposes. These can be enriched with information from master data, CAD data management, or classification systems. The results flow seamlessly into illustrated BOMs within the PLM system, Office exports, or enterprise applications such as PIM systems.

Generate high-quality image data directly from CAD models

Based on existing model data, you automatically generate high-quality image and render data for technical documentation or marketing purposes. These can be enriched with information from master data, CAD data management, or classification systems. The results flow seamlessly into illustrated BOMs within the PLM system, Office exports, or enterprise applications such as PIM systems.

Based on existing model data, you automatically generate high-quality image and render data for technical documentation or marketing purposes. These can be enriched with information from master data, CAD data management, or classification systems. The results flow seamlessly into illustrated BOMs within the PLM system, Office exports, or enterprise applications such as PIM systems.

Related Elements

Manage simulation data and processes in an integrated way

Make simulation methods available company-wide

Accelerate development and simulation processes through automation

Integrate CAD and CAE efficiently – reduce effort and errors

Clearly identify relationships through consistent data management

Get better insights and make faster decisions with 3D product data

Design processes at the push of a button with model data

Use visual analyses and make decisions with the 3D cockpit

Enhance team collaboration by sharing model data

Leverage standards like 3D PDF, JT, and STEP for more possibilities

Accelerate product protection with Digital Mock-ups

Manage product structures and bills of materials securely and efficiently

Ensure compliance through end-to-end documentation of product development

Efficiently configure variants using 150% bills of materials

Compare product structures and drive standardization

Build product architectures across disciplines

Supply downstream processes with reliable data

Plan, implement, and document technical changes

Accelerate change processes through digital workflows and standards

Simplify work with digital folders and Task Manager

Map change processes easily and flexibly and benefit from end-to-end documentation

Validate the analysis of technical changes using 3D models

Combine customer orientation with efficient value creation

Build product portfolios efficiently and strategically

Achieve the ideal balance between customer orientation and cost-effectiveness

Modularize product variability and manage it consistently throughout the product lifecycle

Maintain transparency and clarity even in complex variant spaces

Automatically supply downstream processes with data

Further information

Would you like to find out more about this topic? Choose one of the following information offers.