New CONTACT Elements release

The latest versions of CIM Database PLM and Elements for IoT mark another milestone for the “Digital Thread”. We present some of the innovations in CONTACT’s open low-code platform, which support development, manufacturing, and service professionals to perform their complex tasks even better.

CONTACT’s roadmap for the current Elements release was again filled with improvements and new features, allowing companies to make the most of our end-to-end solutions for product lifecycle management, smart factory, and digital services. Some of the work accomplished by our software development, product management, and UX team already comes to fruition in the Web UI – here we provide a selection of what’s new in our PLM and IoT applications.

Less effort for product changes

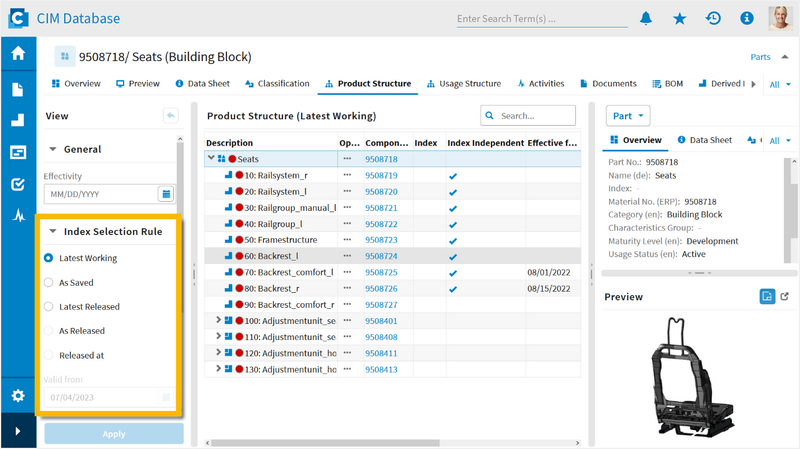

CIM Database PLM now supports the index-independent assembly of components in the bill of materials. The new functionality minimizes efforts for changing product structures. It enables PLM users to access the product structure quickly and easily in the view that best suits their respective task. They can identify all index-independent components for a specific status or release date and have them displayed in a dynamically generated structure.

Dynamic structures offer another significant advantage: when a new component version is incorporated, no changes to the assembly are necessary. CIM Database automatically displays new versions in all index-independent usages, including released product structures. This eliminates the need for revision roll-ups and reduces efforts for changes in existing product structures. Within the same product structure, users can define component assemblies to be both index-independent and index-specific and flexibly select the most suitable option for their context.

Faster cost calculation

CONTACT Product Costing enables companies to reliably calculate the profitability of their products. The PLM module supplies the quotation process with all relevant data and significantly accelerates it. Further improvements have made the application even more efficient and intuitive to use.

New to the standard is the calculation of transport and logistics costs – easily recognizable by a forklift icon. It renders previous configurations obsolete. Purchased parts can now be symbolized by a shopping cart using a simple checkmark. This makes it easier to identify them in complex cost structures.

The new red pencil icon for product components highlights missing cost entries. Even when the menu for product components with subcomponents is collapsed, the icon indicates that at least one subcomponent has not been fully priced. Once all cost attributes are entered, the pencil icon changes to green. Finally, user experience is improved as each cost component has a separate mask now.

Simplified CAx data management

CONTACT’s universal solution for CAx data management now features a new usage list. This simplifies updating the central product database when changes are made to CAD models: Workspaces Desktop displays all referencing documents like assemblies and drawings so that they can be quickly included in the data transfer.

In the E/E domain, we are expanding our portfolio of standard interfaces: Altium projects can now also be managed in Workspaces. Additional highlights include the free choice of a preferred view, a new document view (neatly organized into main assemblies and three subcategories), and simulation data management (SDM). CONTACT Software has developed the SDM plugin for the automated management of CAE documents together with its subsidiary CAIQ. PLM attributes can now be edited locally from all CAD systems.

Digital control of series and order production

CONTACT Elements for IoT is now suitable for all manufacturing processes, whether these are shift-oriented or not. This means that operations can be reported as partially or finally completed at any time, regardless of shifts. Depending on the selected production context, the elements of the Web UI adapt accordingly.

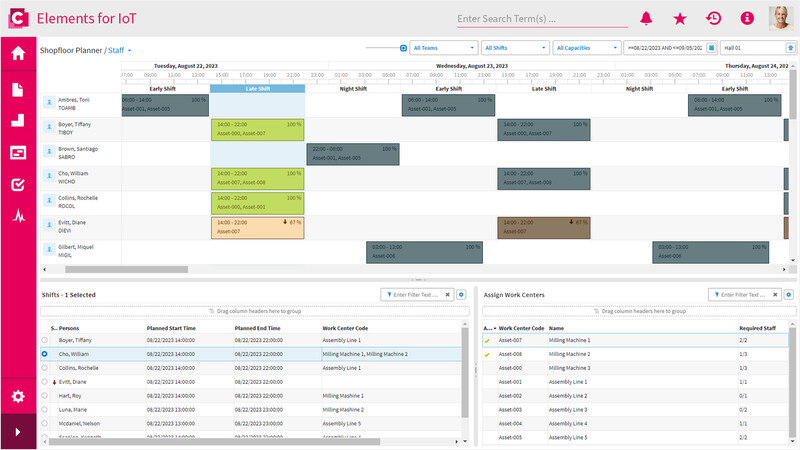

Shift managers can now also use CONTACT’s IoT platform for staff planning. At any time, the new Shopfloor Planner provides them with an overview of who is available, on sick leave, or on vacation. Once scheduling is complete, the app shows which individuals are assigned per machine and shift and indicates planned maintenance and setup times. Through filters and color coding, shift managers can see immediately whether they have allocated too many or too few workers to any shift.

Furthermore, a primary workplace can be defined for each person. He or she will be automatically assigned to this asset, which reduces scheduling efforts.

Checkpoints for better services

CONTACT has included new checkpoints for maintenance, repair, and overhaul activities in its IoT module Customer Services. These can include step-by-step instructions with images and references to the required material. The checkpoints support technicians in executing service cases quicker, better evaluating them, and easily logging time and material expenditures. Once the task is completed, service billing in the ERP system is initiated and product documentation is updated at the push of a button. CONTACT Elements for IoT automatically generates the checkpoint list for an entire plant from the checkpoints of the plant and its subcomponents. The system thereby considers the maintenance frequency of each component.

The Asset Administration Shell (AAS) is a cross-manufacturer standard for the digital twin and holds tremendous potential for data-driven service business. Companies can now effortlessly import the property structure of initial submodels, such as the “Digital Nameplate”, into the Universal Classification of CONTACT Elements. New submodels published by the IDTA will also be made available in our software.

Customers and partners find all information on the latest advancements of our technology platform and its specialist applications in the release notes on our Aloha portal. The new CONTACT Elements release will have its first major appearance in front of industry professionals at the SPS 2023 in November.