Integrate material compliance with analyses to improve products

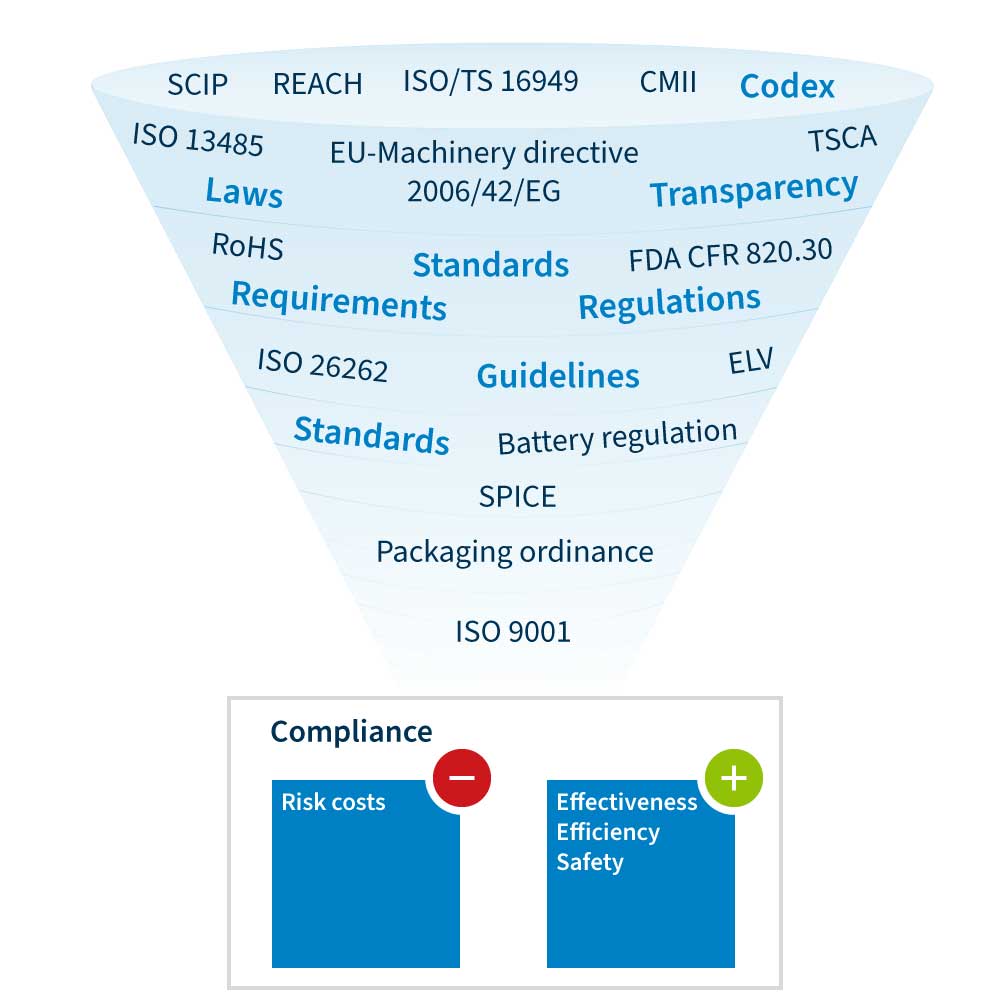

The number of legal requirements for material compliance is continuously increasing: REACH, RoHS, ELV, TSCA, SCIP, SPICE, conflict mineral regulations, packaging and battery directives, as well as countless national and regional provisions. A lack of transparency regarding materials used, manual processes, time-consuming testing/auditing procedures, and increasingly uncertain supply chains pose immense risks. To prevent fines and reputational damage, you must not only cope with material compliance requirements, but proactively manage them. Discover how CONTACT Elements Material Compliance allows you to gain regulatory certainty, fulfill your product responsibility, and improve your products through comprehensive analytical capabilities.

Your benefits

- Gain transparency over the materials used in your products

- Ensure compliance through standard-specific material management

- Increase flexibility and agility through analyses from materials, suppliers, and environmental criteria

- Streamline documentation of regulated material deliveries

- Leverage comprehensive analytical capabilities to improve products and evaluate suppliers

Gain transparency of materials used in your products

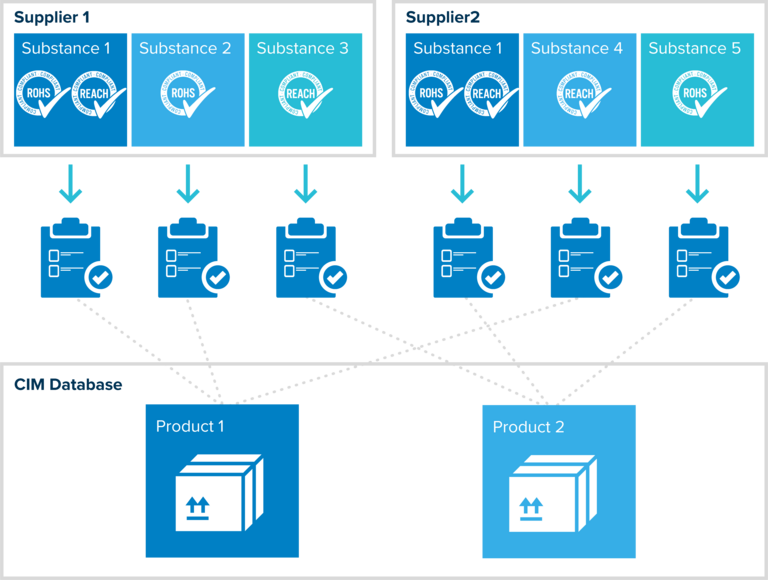

Manufacturing companies must precisely track which materials are incorporated into their products – not least due to stringent legal requirements. This transparency is often lacking in many companies. Because data is inadequately structured and manually maintained, material data relevant for compliance information is incomplete or erroneous. With CONTACT Elements Material Compliance, you link material databases directly with the components of your products. You not only gain complete transparency, but you can also effortlessly provide evidence and instantly identify affected products in the event of necessary material changes.

Manufacturing companies must precisely track which materials are incorporated into their products – not least due to stringent legal requirements. This transparency is often lacking in many companies. Because data is inadequately structured and manually maintained, material data relevant for compliance information is incomplete or erroneous. With CONTACT Elements Material Compliance, you link material databases directly with the components of your products. You not only gain complete transparency, but you can also effortlessly provide evidence and instantly identify affected products in the event of necessary material changes.

Ensure compliance through standard-specific material management

CONTACT Elements Material Compliance enables standard-specific material management, allowing you to meet all regulatory requirements when selecting materials. Define standardized testing processes and supplier information for the key regulations. This enables you to manage materials and components, including all relevant data, and ensure the conformity of the materials used in your products through comprehensive documentation. Supplement your material database with information on sustainability and recycling. Analyses of alternative materials, suppliers, and environmental criteria increase your flexibility and agility.

CONTACT Elements Material Compliance enables standard-specific material management, allowing you to meet all regulatory requirements when selecting materials. Define standardized testing processes and supplier information for the key regulations. This enables you to manage materials and components, including all relevant data, and ensure the conformity of the materials used in your products through comprehensive documentation. Supplement your material database with information on sustainability and recycling. Analyses of alternative materials, suppliers, and environmental criteria increase your flexibility and agility.

Analyze products, materials, and suppliers strategically

For regulated materials, relevant documents such as declarations of conformity or proofs of content should be directly stored within the product data. This makes them readily available to fulfil documentation requirements. CONTACT Elements Material Compliance not only enables the central management of this data but also offers powerful analytical capabilities. Through selection catalogs, you can categorize materials in detail and evaluate them based on criteria such as product, supplier, or substance. This way, you gain valuable insights for identifying alternative materials, optimizing, and evaluating suppliers.

For regulated materials, relevant documents such as declarations of conformity or proofs of content should be directly stored within the product data. This makes them readily available to fulfil documentation requirements. CONTACT Elements Material Compliance not only enables the central management of this data but also offers powerful analytical capabilities. Through selection catalogs, you can categorize materials in detail and evaluate them based on criteria such as product, supplier, or substance. This way, you gain valuable insights for identifying alternative materials, optimizing, and evaluating suppliers.

Anchor sustainability in PLM

In the commentary by consulting firm CIMdata, you learn how to document and reduce the environmental impact of your products with CONTACT Elements.

Related Elements

Manage material information company-wide and ensure sustainability

Make detailed material information available across the entire organization

Collaborate seamlessly with reliable material data

Quickly identify alternative materials

Ensure sustainability and compliance

Provide documentation faster and more reliably

Use integrated project and document management and best practices for your documentation

Integrate in-process documentation in the project plan intelligently and avoid time-consuming subsequent modifications

Automatically generate documentation of deliverables

Organize and utilize know-how enterprise wide

Make all important documents available on every workstation

Save valuable time when searching for documents

Protect valuable know-how

Speed up test and release processes

Comply with regulatory requirements more easily

Further information

Would you like to find out more about this topic? Choose one of the following information offers.