Balance flexibility with process reliability

Modern product development operates within the tension between creative flexibility and reliable process security. While freedom for innovative ideas is essential in early design phases, the demands for data quality, traceability, and reliability increase in later project phases – both internally and in collaboration with partners and suppliers. CONTACT Elements CAx Document Management resolves this dilemma: It comprehensively supports all phases of product development, from the initial idea to the provision of reliable and up-to-date data for all subsequent processes.

Your benefits

- Reliable data management for all central development tools

- Flexibility and creative freedom in early design phases

- Process-reliable availability of results from MCAD and ECAD systems

- Seamless exchange of design data with partners and suppliers

Reliable data management for all central development tools

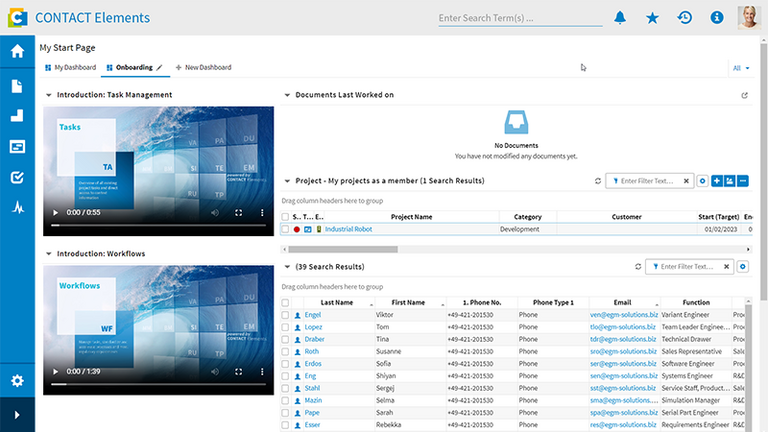

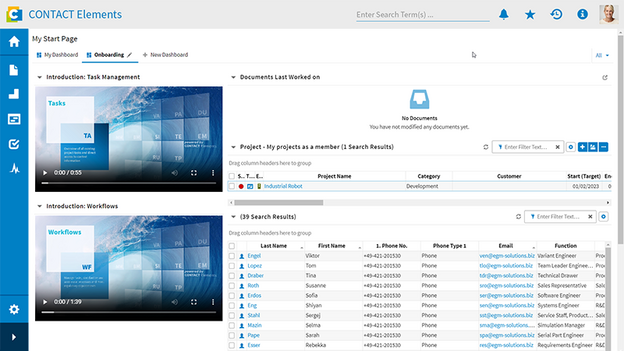

Whether MCAD systems like NX, Catia, Creo, SolidWorks, Solid Edge, and Inventor, or ECAD/EDA solutions such as EPlan, E3-Series, and Altium, these systems form the backbone of any modern development. Given their complex data structures, intelligent Team Data Management is essential. CONTACT's CAx Document Management relieves engineering teams of routine tasks and ensures process reliability and consistent databases. This is achieved through maintained standard interfaces to leading systems and the most powerful multi-CAD data management the market has to offer.

Whether MCAD systems like NX, Catia, Creo, SolidWorks, Solid Edge, and Inventor, or ECAD/EDA solutions such as EPlan, E3-Series, and Altium, these systems form the backbone of any modern development. Given their complex data structures, intelligent Team Data Management is essential. CONTACT's CAx Document Management relieves engineering teams of routine tasks and ensures process reliability and consistent databases. This is achieved through maintained standard interfaces to leading systems and the most powerful multi-CAD data management the market has to offer.

Process-reliable availability of models and drawings

Modern products are composed of a multitude of models and drawings, which serve as a critical basis for all downstream processes – from procurement and simulation to change management, the Digital Twin in production and service. CONTACT’s CAx Document Management enables intelligent data management, allowing you to automatically retrieve all relevant data, convert it if necessary (for example, into 3D PDFs) and make it available. This virtually eliminates manual effort for your employees.

Modern products are composed of a multitude of models and drawings, which serve as a critical basis for all downstream processes – from procurement and simulation to change management, the Digital Twin in production and service. CONTACT’s CAx Document Management enables intelligent data management, allowing you to automatically retrieve all relevant data, convert it if necessary (for example, into 3D PDFs) and make it available. This virtually eliminates manual effort for your employees.

Collaborate efficiently – internally and with partners

Today, teamwork in engineering increasingly crosses company boundaries. CONTACT Elements CAx Document Management supports this on two levels: For internal development teams, workspaces provide maximum creative freedom in early phases by securely synchronizing interim statuses and results with your internal data. For cross-company collaboration, the Collaboration Portal reliably provides tasks and data on the web, proactively informs about changes, and facilitates the integration of external results. This way, all stakeholders – especially clients – retain full transparency, control, and the certainty of up-to-date data at all times.

Collaborate efficiently – internally and with partners

Today, teamwork in engineering increasingly crosses company boundaries. CONTACT Elements CAx Document Management supports this on two levels: For internal development teams, workspaces provide maximum creative freedom in early phases by securely synchronizing interim statuses and results with your internal data. For cross-company collaboration, the Collaboration Portal reliably provides tasks and data on the web, proactively informs about changes, and facilitates the integration of external results. This way, all stakeholders – especially clients – retain full transparency, control, and the certainty of up-to-date data at all times.

Today, teamwork in engineering increasingly crosses company boundaries. CONTACT Elements CAx Document Management supports this on two levels: For internal development teams, workspaces provide maximum creative freedom in early phases by securely synchronizing interim statuses and results with your internal data. For cross-company collaboration, the Collaboration Portal reliably provides tasks and data on the web, proactively informs about changes, and facilitates the integration of external results. This way, all stakeholders – especially clients – retain full transparency, control, and the certainty of up-to-date data at all times.

Related Elements

Get better insights and make faster decisions with 3D product data

Design processes at the push of a button with model data

Use visual analyses and make decisions with the 3D cockpit

Enhance team collaboration by sharing model data

Leverage standards like 3D PDF, JT, and STEP for more possibilities

Accelerate product protection with digital mockups

Manage product structures and bills of materials securely and efficiently

Ensure compliance through end-to-end documentation of product development

Efficiently configure variants using 150% bills of materials

Compare product structures and drive standardization

Build product architectures across disciplines

Supply downstream processes with reliable data

Combine customer orientation with efficient value creation

Build product portfolios efficiently and strategically

Achieve the ideal balance between customer orientation and cost-effectiveness

Modularize product variability and manage it consistently throughout the product lifecycle

Maintain transparency and clarity even in complex variant spaces

Automatically supply downstream processes with data

Integrally manage simulation data and processes

Make simulation methods available enterprise-wide

Accelerate development and simulation processes through automation

Efficiently integrate CAD and CAE – reduce effort and errors

Clearly define relationships using consistent data management

Further information

Would you like to find out more about this topic? Choose one of the following information offers.