Harnessing IoT potential for condition monitoring and data analysis is a must

Material damage, wear and tear, environmental influences, and operating errors are the most frequent causes of malfunctions in industrial plants. Any consequences, such as the production of rejects or machine downtime, cause considerable economic damage. Using IoT technology for condition monitoring and data analysis not only reduces maintenance costs and downtime but also increases production capacity and extends the service life of machinery and equipment. The Elements for IoT module Monitoring & Analytics provides a comprehensive basis.

Benefits

- Using data science and analytics as the basis for data-driven processes

- Process large amounts of data automatically

- Automate condition monitoring and minimize downtime

- Enable complex analyses with templates at the push of a button

- Keep assets in view with dashboards and manage them securely with key performance indicators

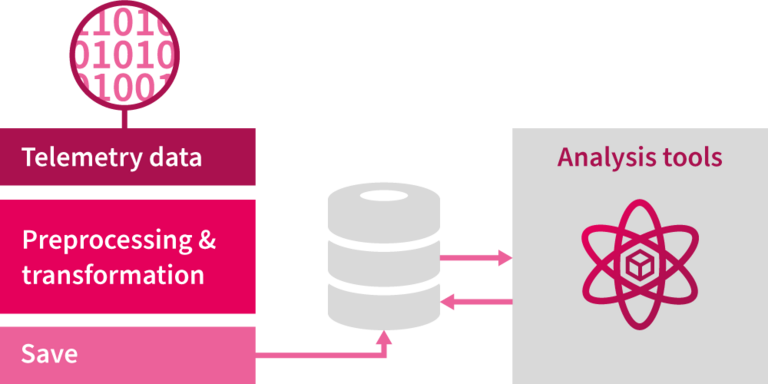

Turn Big Data into Smart Data

Devices and machines deliver large amounts of data. Use the possibilities of data science and analytics as the basis for data-driven processes and transform mass data into smart data. With Elements for IoT, automated pre-processing steps ensure this information is stored in the correct format – for example, through unit conversion. For subsequent analysis, cleansing and consolidation processes, Elements for IoT integrates open source tools or your analysis tools to support your optimization processes.

Turn Big Data into Smart Data

Devices and machines deliver large amounts of data. Use the possibilities of data science and analytics as the basis for data-driven processes and transform mass data into smart data. With Elements for IoT, automated pre-processing steps ensure this information is stored in the correct format – for example, through unit conversion. For subsequent analysis, cleansing and consolidation processes, Elements for IoT integrates open source tools or your analysis tools to support your optimization processes.

Devices and machines deliver large amounts of data. Use the possibilities of data science and analytics as the basis for data-driven processes and transform mass data into smart data. With Elements for IoT, automated pre-processing steps ensure this information is stored in the correct format – for example, through unit conversion. For subsequent analysis, cleansing and consolidation processes, Elements for IoT integrates open source tools or your analysis tools to support your optimization processes.

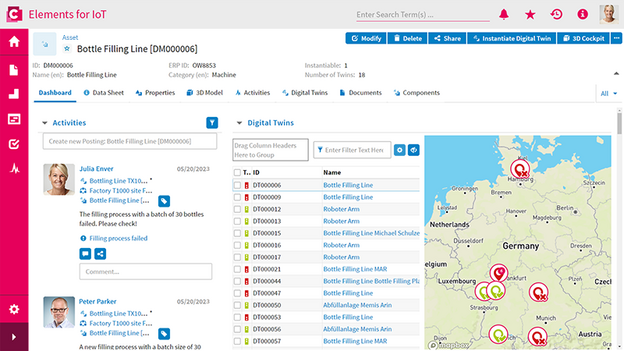

Monitor your machines and assets

You can define tolerance ranges for incoming operational data. Elements for IoT uses live data to monitor the condition of your machines and devices (condition monitoring) and automatically triggers predefined processes when tolerance ranges are exceeded. In the event of an incident, the responsible departments are automatically notified and the necessary measures or follow-up processes are triggered. This minimizes downtime and improves production quality. At the same time, you can offer customers additional services such as predictive maintenance.

Monitor your machines and assets

You can define tolerance ranges for incoming operational data. Elements for IoT uses live data to monitor the condition of your machines and devices (condition monitoring) and automatically triggers predefined processes when tolerance ranges are exceeded. In the event of an incident, the responsible departments are automatically notified and the necessary measures or follow-up processes are triggered. This minimizes downtime and improves production quality. At the same time, you can offer customers additional services such as predictive maintenance.

You can define tolerance ranges for incoming operational data. Elements for IoT uses live data to monitor the condition of your machines and devices (condition monitoring) and automatically triggers predefined processes when tolerance ranges are exceeded. In the event of an incident, the responsible departments are automatically notified and the necessary measures or follow-up processes are triggered. This minimizes downtime and improves production quality. At the same time, you can offer customers additional services such as predictive maintenance.

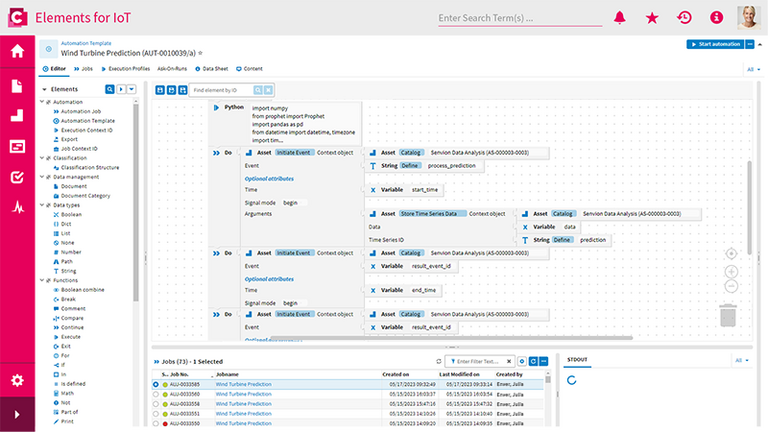

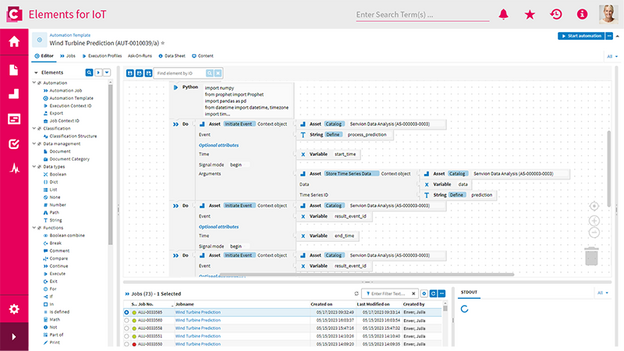

Advanced analytics at the push of a button

In particularly demanding applications, such as predictive maintenance, the available data are input variables for simulations or complex calculations. Data analysts can use CONTACT's PowerApplications to model and provide calculations as templates in a graphical programming interface. This means that complex analyses, evaluations or data preparation can be carried out by everyone in the team at the touch of a button. Specialist departments are thus able to act independently without the limited resources of data analysts.

Advanced analytics at the push of a button

In particularly demanding applications, such as predictive maintenance, the available data are input variables for simulations or complex calculations. Data analysts can use CONTACT's PowerApplications to model and provide calculations as templates in a graphical programming interface. This means that complex analyses, evaluations or data preparation can be carried out by everyone in the team at the touch of a button. Specialist departments are thus able to act independently without the limited resources of data analysts.

In particularly demanding applications, such as predictive maintenance, the available data are input variables for simulations or complex calculations. Data analysts can use CONTACT's PowerApplications to model and provide calculations as templates in a graphical programming interface. This means that complex analyses, evaluations or data preparation can be carried out by everyone in the team at the touch of a button. Specialist departments are thus able to act independently without the limited resources of data analysts.

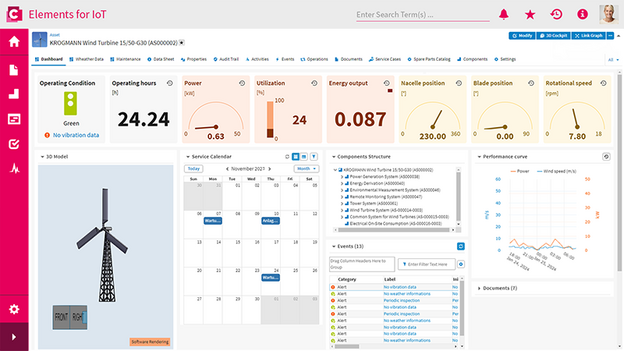

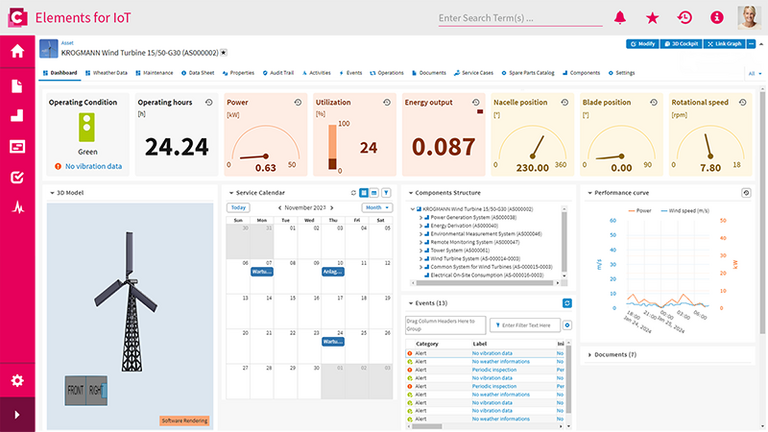

Gain overview with dashboards and define metrics

Use Elements for IoT for comprehensive monitoring and get an overview with easy-to-create and customize dashboards. CONTACT's modern web UI lets you monitor and analyze machines, devices, and fleets. You can use a wide catalog of widgets and a variety of graphs, and freely define KPIs for the most relevant operational data.

Gain overview with dashboards and define metrics

Use Elements for IoT for comprehensive monitoring and get an overview with easy-to-create and customize dashboards. CONTACT's modern web UI lets you monitor and analyze machines, devices, and fleets. You can use a wide catalog of widgets and a variety of graphs, and freely define KPIs for the most relevant operational data.

Use Elements for IoT for comprehensive monitoring and get an overview with easy-to-create and customize dashboards. CONTACT's modern web UI lets you monitor and analyze machines, devices, and fleets. You can use a wide catalog of widgets and a variety of graphs, and freely define KPIs for the most relevant operational data.

How to digitalize asset management

Digital asset management increases the availability and service life of your machines and plants. In our guide, you can learn how to minimize downtime and production interruptions, plan maintenance cycles based on live operating data, avoid emergency repairs, and make data-driven decisions.

How to digitalize asset management

Digital asset management increases the availability and service life of your machines and plants. In our guide, you can learn how to minimize downtime and production interruptions, plan maintenance cycles based on live operating data, avoid emergency repairs, and make data-driven decisions.

Digital asset management increases the availability and service life of your machines and plants. In our guide, you can learn how to minimize downtime and production interruptions, plan maintenance cycles based on live operating data, avoid emergency repairs, and make data-driven decisions.

Related Elements

Transparency and controllability for your production processes

Maximize availability of machinery and equipment

Basis for continuous improvement of production processes

Transparency from shopfloor to management

Live data from production for smooth processes – from machine control to management reports

Efficient support and flexible coordination of production teams

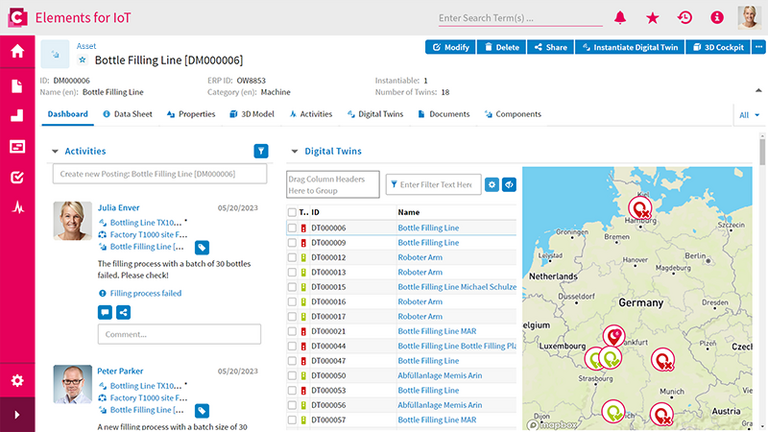

Use the virtual representation of devices in the field for product and process improvements

Establish the digital twin as a database for all IoT business processes

Create complete profiles across the entire lifecycle of your products and map changes in the field

Use the digital twin as a basis for creating added value for your customers

Simple integration of devices – creating added value with operating data

Device fleets easy to record, connect and remote control

Optimize maintenance processes and extend service life

Added value through machine extension and generation

Monitor the network status of IoT gateways

Perform software updates of fleets in one step

Increase customer satisfaction through digital services around the operation of your products

Digitalize service processes from offer to invoice

Generate more service business with best practice templates

Manage services for a wide range of customers easily

Improve customer loyalty with pay-per-use business models

Further Information

Would you like to find out more about this topic? Choose one of the following information offers.