Requirements management is the key to project success

Inadequate or lack of requirements management is one of the most common causes of project goals being missed. Unclear communication channels between stakeholders, a lack of documentation and a lack of understanding of requirements on the part of the development team inhibit collaborative product development and lead to serious problems. Examples of this are flawed designs, delays in the development process, exploding costs, poor product quality or unfulfilled requirements. CONTACT Elements Requirements Engineering helps you to ensure the success of your projects and avoid costly mistakes.

Benefits

- Automatically monitor and document requirement lifecycles

- Record and edit requirements easily and conveniently

- Clearly display relationships between requirements in the virtual product model

- Directly monitor the degree of fulfillment and corrective measures

- Implement systems engineering reliably according to the V-model and other methods

Automatically monitor and document requirement lifecycles

Requirements Engineering enables you to master the management of large requirements portfolios. Record and track new requirements and changes throughout the development process. The audit trail documents all changes and makes them directly traceable in detail. Use the integrated ReqIF format to exchange requirements with customers or external partners easily and efficiently: Export your status and integrate new statuses directly after processing by customers or service providers. You can also use baselining to save intermediate statuses or combinations of statuses and compare them using any parameters such as acceptance criteria, open points or semantic links.

Automatically monitor and document requirement lifecycles

Requirements Engineering enables you to master the management of large requirements portfolios. Record and track new requirements and changes throughout the development process. The audit trail documents all changes and makes them directly traceable in detail. Use the integrated ReqIF format to exchange requirements with customers or external partners easily and efficiently: Export your status and integrate new statuses directly after processing by customers or service providers. You can also use baselining to save intermediate statuses or combinations of statuses and compare them using any parameters such as acceptance criteria, open points or semantic links.

Requirements Engineering enables you to master the management of large requirements portfolios. Record and track new requirements and changes throughout the development process. The audit trail documents all changes and makes them directly traceable in detail. Use the integrated ReqIF format to exchange requirements with customers or external partners easily and efficiently: Export your status and integrate new statuses directly after processing by customers or service providers. You can also use baselining to save intermediate statuses or combinations of statuses and compare them using any parameters such as acceptance criteria, open points or semantic links.

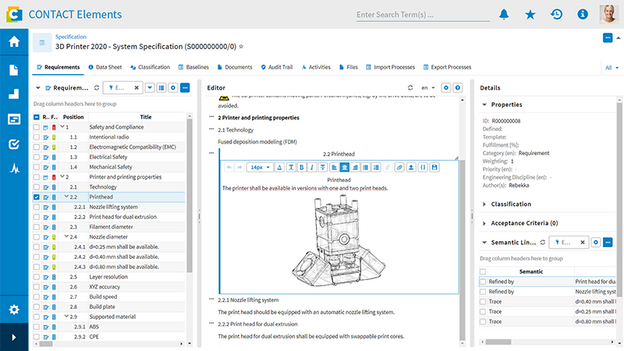

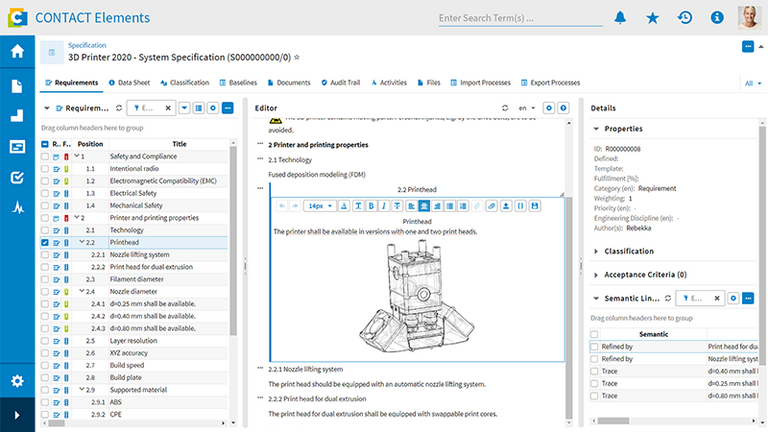

Record and edit requirements easily and conveniently

With the editor integrated in the module, you can create and edit specifications, their requirements, and acceptance criteria web-based. You can add layouts and other image information. In addition, the Specification Editor makes it easy to classify and evaluate requirements and offers convenience functions such as preview and batch modifications. Furthermore, responsible persons can easily assign evaluators. They automatically receive tasks for evaluating the specifications. The status of the evaluation tasks can be tracked clearly.

Record and edit requirements easily and conveniently

With the editor integrated in the module, you can create and edit specifications, their requirements, and acceptance criteria web-based. You can add layouts and other image information. In addition, the Specification Editor makes it easy to classify and evaluate requirements and offers convenience functions such as preview and batch modifications. Furthermore, responsible persons can easily assign evaluators. They automatically receive tasks for evaluating the specifications. The status of the evaluation tasks can be tracked clearly.

With the editor integrated in the module, you can create and edit specifications, their requirements, and acceptance criteria web-based. You can add layouts and other image information. In addition, the Specification Editor makes it easy to classify and evaluate requirements and offers convenience functions such as preview and batch modifications. Furthermore, responsible persons can easily assign evaluators. They automatically receive tasks for evaluating the specifications. The status of the evaluation tasks can be tracked clearly.

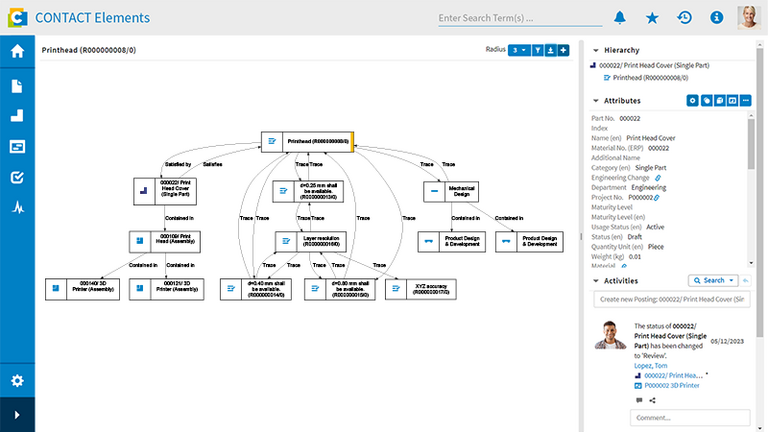

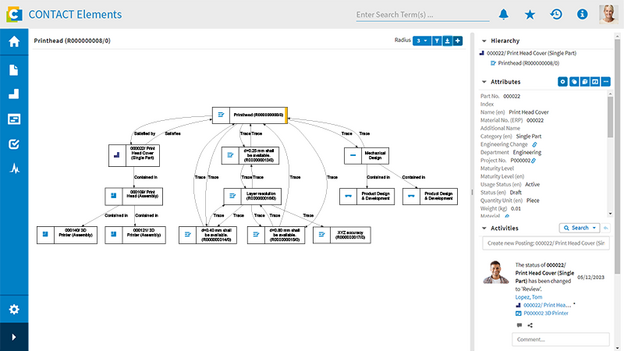

Clearly display relationships between requirements in the virtual product model

Semantic Links enables you to easily link requirements to each other and to other objects such as components or tasks. The resulting link graphvisualizes these interrelations and helps you recognize and evaluate the impact of changes in advance. Filters and navigation functions help keep track of complex projects in particular.

Clearly display relationships between requirements in the virtual product model

Semantic Links enables you to easily link requirements to each other and to other objects such as components or tasks. The resulting link graphvisualizes these interrelations and helps you recognize and evaluate the impact of changes in advance. Filters and navigation functions help keep track of complex projects in particular.

Semantic Links enables you to easily link requirements to each other and to other objects such as components or tasks. The resulting link graphvisualizes these interrelations and helps you recognize and evaluate the impact of changes in advance. Filters and navigation functions help keep track of complex projects in particular.

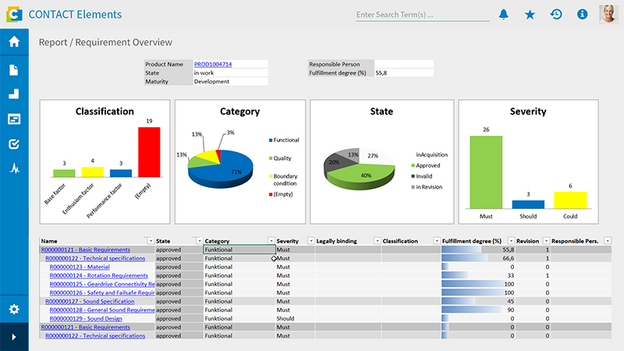

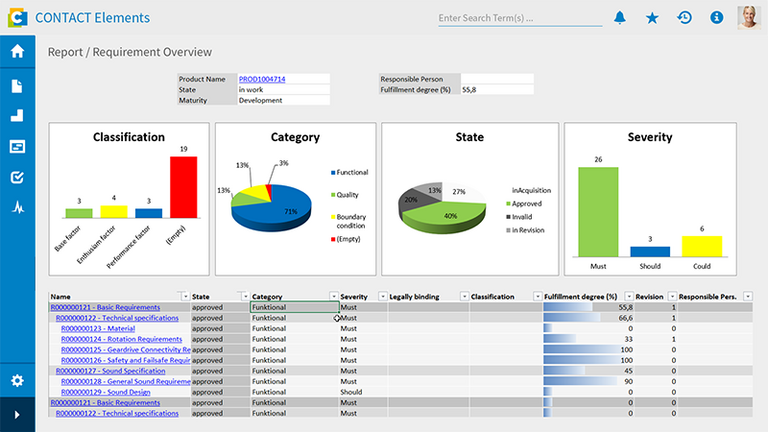

Monitor the degree of fulfillment and take corrective action

CONTACT Requirements Engineering allows you to plan and monitor requirements and the degree to which they are fulfilled, both as objects in their own right and in conjunction with tasks from the project plan. Requirements that have been fulfilled can be recorded either manually or automatically – for example the proportion of certain materials for compliance with RoHS. Clearly structured charts indicate the degree to which requirements have been fulfilled. If there are any significant discrepancies, countermeasures can be taken and traced without any need for separate additional tools.

Monitor the degree of fulfillment and take corrective action

CONTACT Requirements Engineering allows you to plan and monitor requirements and the degree to which they are fulfilled, both as objects in their own right and in conjunction with tasks from the project plan. Requirements that have been fulfilled can be recorded either manually or automatically – for example the proportion of certain materials for compliance with RoHS. Clearly structured charts indicate the degree to which requirements have been fulfilled. If there are any significant discrepancies, countermeasures can be taken and traced without any need for separate additional tools.

CONTACT Requirements Engineering allows you to plan and monitor requirements and the degree to which they are fulfilled, both as objects in their own right and in conjunction with tasks from the project plan. Requirements that have been fulfilled can be recorded either manually or automatically – for example the proportion of certain materials for compliance with RoHS. Clearly structured charts indicate the degree to which requirements have been fulfilled. If there are any significant discrepancies, countermeasures can be taken and traced without any need for separate additional tools.

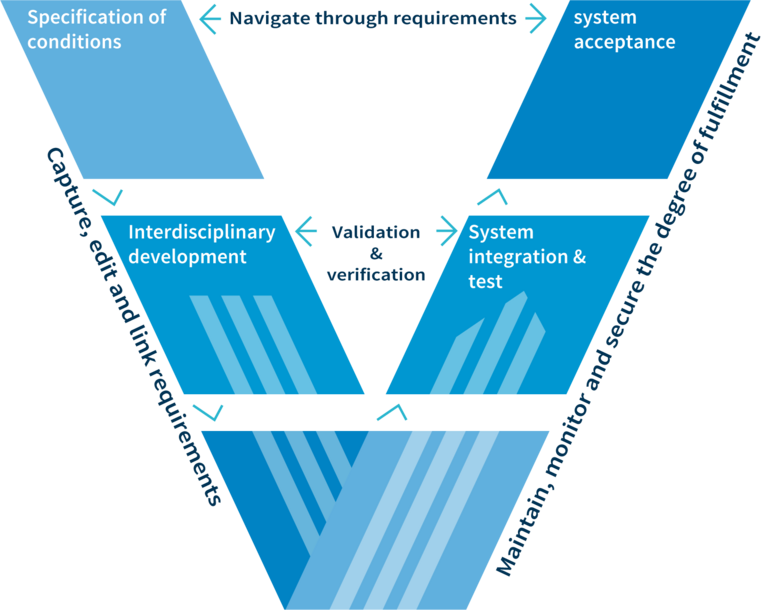

Provide practice-oriented support for systems engineering

Requirements Engineering supports product development in accordancewith the enhanced V-model. End-to-end, requirements-driven development is a a crucial lever for systems engineering or Model Based Systems Engineering (MBSE). The result is transparency, traceability, compliance and reliably achieved objectives throughout the entire development process and across the individual disciplines such as mechanical engineering, E/E and software.

Provide practice-oriented support for systems engineering

Requirements Engineering supports product development in accordancewith the enhanced V-model. End-to-end, requirements-driven development is a a crucial lever for systems engineering or Model Based Systems Engineering (MBSE). The result is transparency, traceability, compliance and reliably achieved objectives throughout the entire development process and across the individual disciplines such as mechanical engineering, E/E and software.

Requirements Engineering supports product development in accordancewith the enhanced V-model. End-to-end, requirements-driven development is a a crucial lever for systems engineering or Model Based Systems Engineering (MBSE). The result is transparency, traceability, compliance and reliably achieved objectives throughout the entire development process and across the individual disciplines such as mechanical engineering, E/E and software.

Combine MBSE and PLM to implement state-of-the-art development processes

In today’s world, it is hard to image innovation without interdisciplinary team work. The growing proportion of software in products is a key driver for innovative products. This gives rise to an enormous number of dependencies between disciplines and their work products within the development process. This white paper shows how Model-based Systems Engineering (MBSE) can simplify and accelerate the development process and why it is worth integrating MBSE and Product Lifecycle Management (PLM). It is widely accepted that the potential of MBSE can only be fully exploited, if it is integrated in a collaborative environment by means of robust processes. This is exactly where the intrinsic strengths of PLM lie.

Requirements Engineering is tool qualified for ISO 26262 standards

CONTACT Elements is tool-qualified by TÜV Nord in accordance with ISO 26262. In addition to the CONTACT Elements platform, the international technology expert for security has certified the products CIM Database for PLM and Project Office for project management as well as Requirements Engineering and a number of other CONTACT Elements software modules. With this certification, TÜV Nord assures that our software fulfills the requirements of ISO 26262 for standards for software tools for the development of safety-relevant properties.

Related Elements

Ensure the compliance of materials with industry and regulatory standards such as REACH and RoHS during the development process

Ensure a transparent view of the materials used in your products

Make sure that only permitted materials are processed

Quality-tested delivery of regulated materials

Seamless documentation of the lifecycle of documents and other PLM objects

With Audit Trails, you can seamlessly trace the lifecycle of documents and PLM objects

Collate important regulatory documents conveniently in folders

Use digital lifecycle records to ensure audit trail capability and improve the utilization of your products and machines

Faster, more reliable availability of project, product and customer documentation

Use integrated project and document management and best practices for your documentation

Integrate in-process documentation in the project plan intelligently and avoid time-consuming subsequent modifications

Automatically generate documentation of deliverables

Overview of all existing project tasks and direct access to context information

Use tasks to set the course for a smooth transition from project planning to implementation

Allow your project participants an optimal self-organization

•Connect reliability with agility and keep track of the multi-project mode

Indicator-based project controlling: Monitor progress, improve performance and achieve targets

Define indicators for products, projects and processes to improve your performance

Specify target values for product attributes and record actions to be taken in the event of discrepancies

Keep an eye on your indicators and the success of actions taken at all times

Further information

Would you like to find out more about this topic? Choose one of the following information offers.