Digital Twin

For years, Gartner has classified the digital twin as one of the ten most important technology trends.1 The use of technology in product development, production and service promises enormous benefits. These can be achieved by monitoring the behavior of products and production processes with the help of a digital twin, developing new customer-oriented services or drawing conclusions for product improvements from the product data. Companies are faced with the question of how best to implement digital twin applications in their processes in order to exploit the benefits of this technology.

The digital twin is the virtual representation of a physical product or system in the field, whereby according to the Wikipedia definition it is irrelevant whether the counterpart already exists or will exist in the future.2 It offers the possibility of linking the configuration of the delivered product instance with the operational and environmental data occurring in the field and of monitoring and controlling the product instance remotely. How completely the twin depicts reality depends on the use case. There is not one twin, but different characteristics depending on the particular use case:

- the digital product twin, which serves to virtually put the product into operation and improve it with the help of the operating data,

- the digital factory twin, which supports the planning, monitoring and optimization of production processes in the sense of Industry 4.0, and

- the digital service twin, which accompanies the real product in operation and enables services such as predictive or prescriptive maintenance.3

IoT brings the digital twin to life

According to Deloitte, the Internet of Things (IoT) is an obligatory pre-stage for the digital twin.4 However, this opinion is not uncontroversial, as the concept originates from a time when the IoT did not yet exist and was strongly rooted in the PLM world.5 In addition, there are application examples in the area of augmented reality in which the digital twin manages without IoT. It is indisputable, however, that the digital twin only really comes to life in conjunction with IoT, Big Data Analytics and Artificial Intelligence.

On the other hand, there are case studies in which the digital twin unfolds its own life detached from the PLM world. But only in combination with PLM, it can accompany the real object like a digital shadow over the entire product lifecycle, e.g. to automatically update the software in a delivered product instance or to play back the information from the operating phase into development. The continuous connection of PLM and IoT is also referred to as digital thread.6

From digital master to digital twin

In order to ensure digital consistency, the digital twin is derived from the digital master as a concrete characteristic of an instance of the product or system.7 In addition to the geometry data, this Master also includes parts lists and variant configuration(s), but is more than just a digital product model with all variants. It serves to predefine the essential properties and functions of digital twins of the same type in a kind of template, so that they do not have to be recorded individually for each twin. The digital master supports standardization and can be used as a starting point for evaluating the behavior of a set of similar twins. In order to be able to link a specific version of the digital twin with the operating data from the field or production, these unstructured mass data must be prepared and evaluated. As a rule, advanced data analytics and AI methods are used, which are an essential component of IoT platforms. There is an increasing trend towards edge computing, i.e. data preparation close to the sensor, so that huge amounts of data do not have to be sent to the cloud.8

Wide range of possible use cases

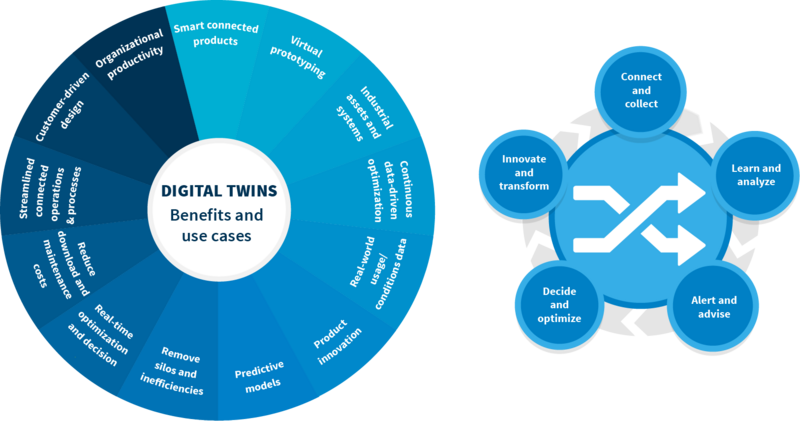

Production technology is undoubtedly one of the most important areas of application for digital twins in view of autonomous manufacturing and industry 4.0. According to Deloitte, however, there is also a wide range of uses from connected car applications to energy supply, healthcare, logistics and telecommunications. Market analysts therefore assume that the technology will establish itself on a broad front in the coming years. Gartner predicts that by 2021, half of the major companies in the manufacturing industry will be using digital twin.9

The digital mirroring of objects in the field enables the most diverse types of analyses, which can lead to comprehensive corrective and optimization measures. In this sense, digital twins are also a new tool for education: Instead of having to study and experiment with the real object, the digital replica can be used.10

Left: The many application areas of digital twins and their benefits; right: Application in different learning fields

(adapted from Colin J. Parris, 2016)

PLM-related IoT platforms as the basis for the digital thread

Generally, a digital twin can be set up for each smart networked object. During implementation, companies must therefore first decide which application promises the greatest benefit for them, what information they need for this purpose and whether they have access to this information at all. For example, it would make little sense to equip machines with sensors for predictive maintenance and set up a service twin if the buyers of this machine refused access to operating data. On the other hand, buyers may well require a digital twin of the machine in order to simulate and optimize the production process in their plant.

Ultimately, the use case also determines which IoT modules the company in question needs. The choice of a PLM-related IoT platform can help to minimize the effort required to ensure digital consistency in the sense of the digital thread. Most PLM manufacturers today offer such platforms.

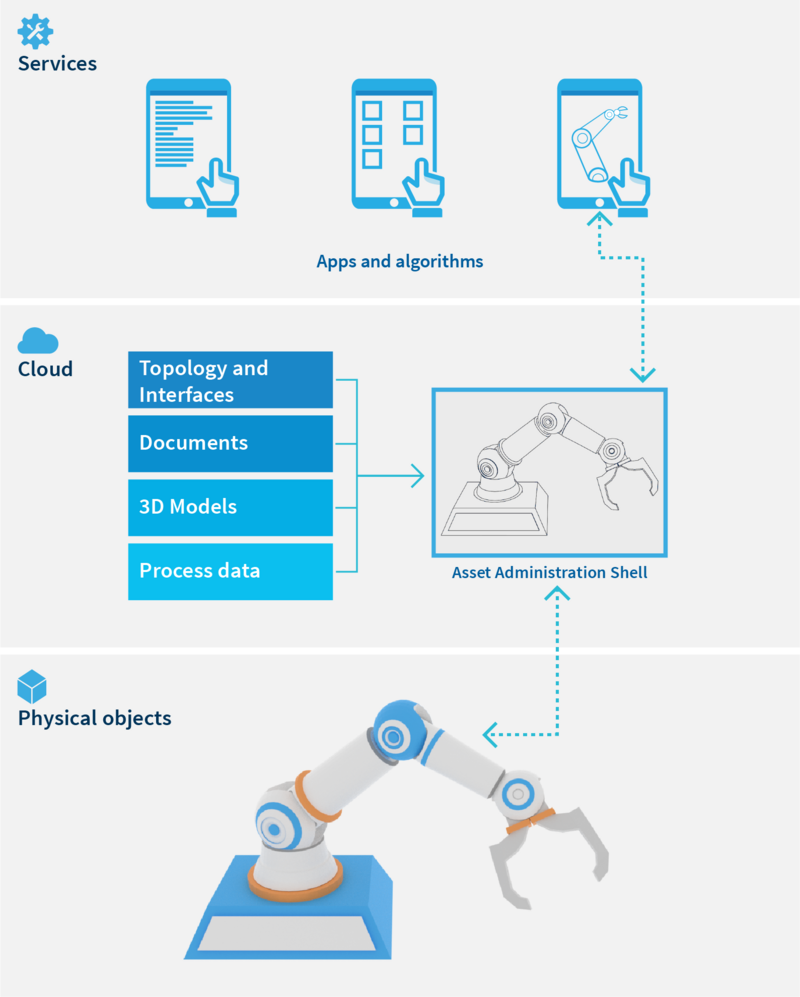

The future of the digital twin: the industrial revolution

The future digital twin will contain both data and interfaces. It will be a multi-faceted digital counterpart to the real asset, embedded in an IoT/Industry 4.0 ecosystem. It will act as an access point for a new generation of applications and algorithms and as a mediator between future IoT/Industry 4.0 services and the real world.

Three-stage concept of a cyberphysical system (adapted from Rainer Drath & Alexander Horch, 2014)

Industry 4.0 is often understood as the application of the generic concept of cyber-physical systems to industrial production systems.11 In a cyber-physical system of an IoT/Industry 4.0 environment, the digital twin connects the physical world with the IoT/Industry 4.0 service world.

Even if the term Industry 4.0 has caused some confusion in part due to overambitious marketing: The revolutionary aspect it contains accurately describes the fundamental structural change in industry. The digital twin, in combination with cloud technology, apps and algorithms, has the potential to revolutionize every aspect of industry. "Only with the digital twin can companies set the right course toward the future."12

Sources

1 Gartner: Top 10 Strategic Technology Trends for 2018 (retrieved 14.12.2018)

2 Wikipedia: Digital Twin (retrieved 14.12.2018)

3 Aktuelle Technik: Digitaler Zwilling – Herz der Digitalisierung (retrieved 14.12.2018)

4 Deloitte: Grenzenlos vernetzt: Digital Twins. Smarte Vernetzung durch IoT, Digitale Zwillinge und die Supra-Plattform. (retrieved 14.12.2018)

5 i-SCOOP: Digital twin technology and simulation: benefits, usage and predictions 2018 (retrieved 14.12.2018)

6 Industry Week: Demystifying the Digital Thread and Digital Twin Concepts (retrieved 14.12.2018)

7 CONTACT Software: Der Digitale Zwilling erschließt neue Geschäftsfelder (retrieved 14.12.2018)

8 G2Crowd: Edge Computing (retrieved 14.12.2018)

9 Gartner: Prepare for the Impact of Digital Twins (retrieved 14.12.2018)

10 IEEE Future Directions: What would education be like in 2050? Digital Twins (retrieved 04.02.2019)

11 ResearchGate/Rainer Drath and Alexander Horch: Industrie 4.0: Hit or hype? [Industry Forum] (retrieved 05.02.2019)

12 Computerwoche: Wer braucht den Digitalen Zwilling wirklich? (retrieved 23.02.2021)

Further information

- i-SCOOP: Digital twins – rise of the digital twin in Industrial IoT and Industry 4.0 (retrieved 14.12.2018)

- G2Crowd: Digital Twins (retrieved 14.12.2018)

- Deloitte: Industry 4.0 and the digital twin (retrieved 14.12.2018)

- Medium: Why Digital Twins are set to transform products and businesses (retrieved 14.12.2018)