Pre-series crucial for success of series production

The management of tests and pre-series stands is costly and time-consuming. At the same time, pre-series are crucial for the success of mass production. Prototypes and samples are manufactured individually through complex coordination processes. In this process, it is necessary to procure pre-series parts, while the bill of materials is still in development, and at the same time to manage testing and prototyping and to meet critical compliance requirements. and prototyping at the same time, as well as meeting critical compliance requirements. With the extensive and small-scale material planning and many changes common in pre-production, there is a significant risk in proceeding without appropriate support. Test Management & Ramp-up offers a remedy: The Elements building block module ensures a smooth transition from pre-series to production.

Benefits

- Process reliability in the pre-series through unique support

- Solid mapping and cost-efficient control of series ramp-up

- Precise and on-time scheduling with prototype bill of materials

- Reliable control and documentation of activities in prototyping and testing

- Transparency of interrelationships between product and tools

Ensure process reliability in pre-series through unique support

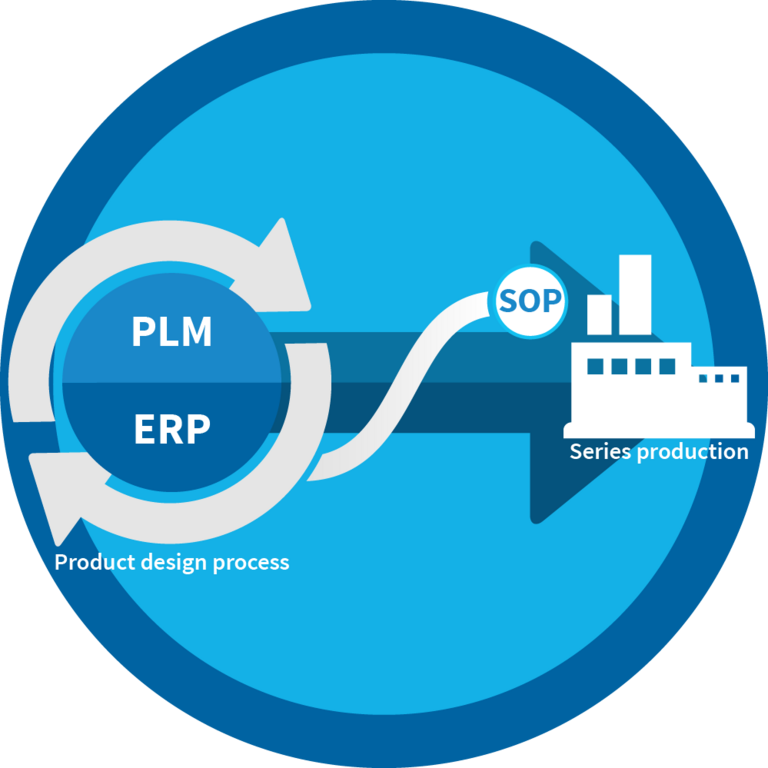

Pre-series represents the path from the virtual product model via samples and prototypes to the start of series production and start of production (SOP). In this phase, you need to define sample sizes, plan pre-production parts, manage prototyping and testing, and synchronize toolmaking. You procure parts while the BOMs are still in development. Disciplines such as development, purchasing, prototyping, tooling, and production coordinate with each other. At the same time, critical compliance requirements must be met − for example, you must document the build status and life cycle of your samples and prototypes. With CONTACT's solution, you ensure transparency and process reliability in the transition phase between development and production.

Ensure process reliability in pre-series through unique support

Pre-series represents the path from the virtual product model via samples and prototypes to the start of series production and start of production (SOP). In this phase, you need to define sample sizes, plan pre-production parts, manage prototyping and testing, and synchronize toolmaking. You procure parts while the BOMs are still in development. Disciplines such as development, purchasing, prototyping, tooling, and production coordinate with each other. At the same time, critical compliance requirements must be met − for example, you must document the build status and life cycle of your samples and prototypes. With CONTACT's solution, you ensure transparency and process reliability in the transition phase between development and production.

Pre-series represents the path from the virtual product model via samples and prototypes to the start of series production and start of production (SOP). In this phase, you need to define sample sizes, plan pre-production parts, manage prototyping and testing, and synchronize toolmaking. You procure parts while the BOMs are still in development. Disciplines such as development, purchasing, prototyping, tooling, and production coordinate with each other. At the same time, critical compliance requirements must be met − for example, you must document the build status and life cycle of your samples and prototypes. With CONTACT's solution, you ensure transparency and process reliability in the transition phase between development and production.

Map your series ramp-up solidly and control it cost-efficiently

In the transition from PLM-controlled development processes to ERP-controlled series processes, a uniform database for the pre-series is usually missing. Departments therefore make do with error-prone on-board tools such as Excel and e-mail communication. With Test Management & Ramp-up you can close this gap. The solid mapping of cost-intensive pre-series processes makes them secure and transparent.

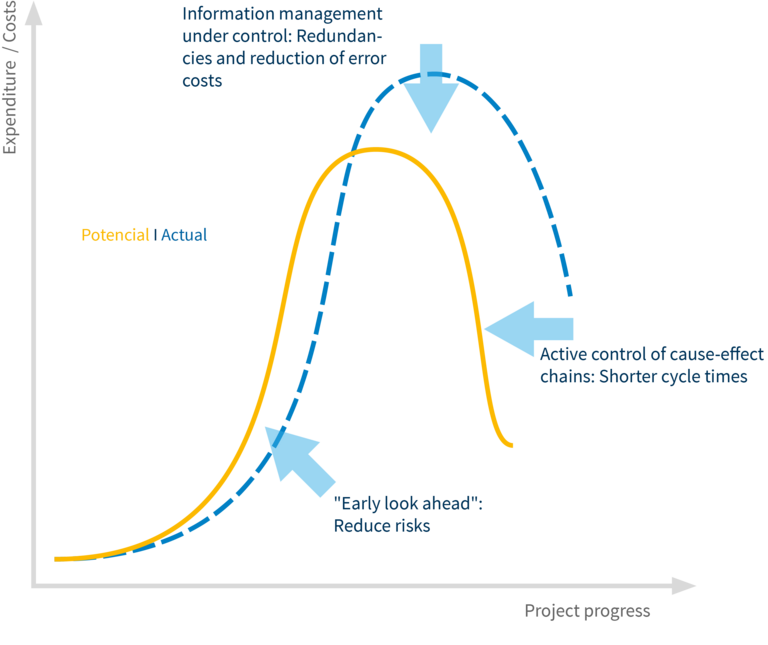

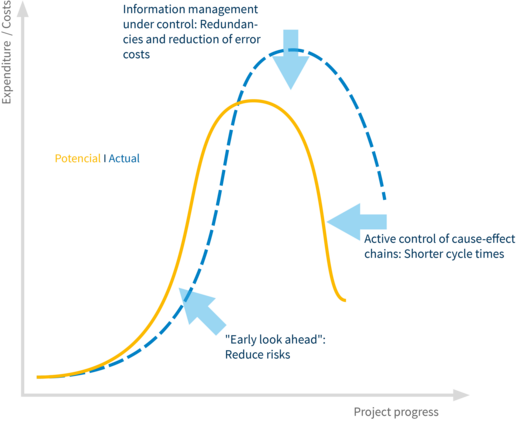

Reduce errors − increase adherence to schedules

Test Management & Ramp-up enables control of all pre-series processes. The solution makes the effects of design or schedule changes on prototyping, testing, and tooling transparent across disciplines. In this way, you avoid parallel work, coordination problems and thus costly corrections and rework. The bottom line for you is: higher adherence to schedules, fewer errors, and cost efficiency in the transition from development to production!

Map your series ramp-up solidly and control it cost-efficiently

In the transition from PLM-controlled development processes to ERP-controlled series processes, a uniform database for the pre-series is usually missing. Departments therefore make do with error-prone on-board tools such as Excel and e-mail communication. With Test Management & Ramp-up you can close this gap. The solid mapping of cost-intensive pre-series processes makes them secure and transparent.

Reduce errors − increase adherence to schedules

Test Management & Ramp-up enables control of all pre-series processes. The solution makes the effects of design or schedule changes on prototyping, testing, and tooling transparent across disciplines. In this way, you avoid parallel work, coordination problems and thus costly corrections and rework. The bottom line for you is: higher adherence to schedules, fewer errors, and cost efficiency in the transition from development to production!

In the transition from PLM-controlled development processes to ERP-controlled series processes, a uniform database for the pre-series is usually missing. Departments therefore make do with error-prone on-board tools such as Excel and e-mail communication. With Test Management & Ramp-up you can close this gap. The solid mapping of cost-intensive pre-series processes makes them secure and transparent.

Reduce errors − increase adherence to schedules

Test Management & Ramp-up enables control of all pre-series processes. The solution makes the effects of design or schedule changes on prototyping, testing, and tooling transparent across disciplines. In this way, you avoid parallel work, coordination problems and thus costly corrections and rework. The bottom line for you is: higher adherence to schedules, fewer errors, and cost efficiency in the transition from development to production!

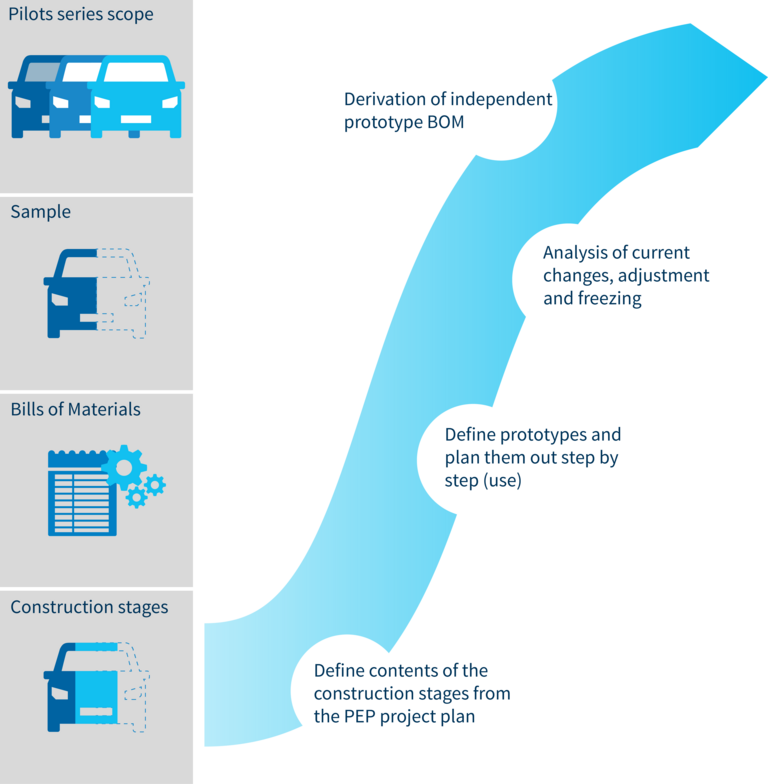

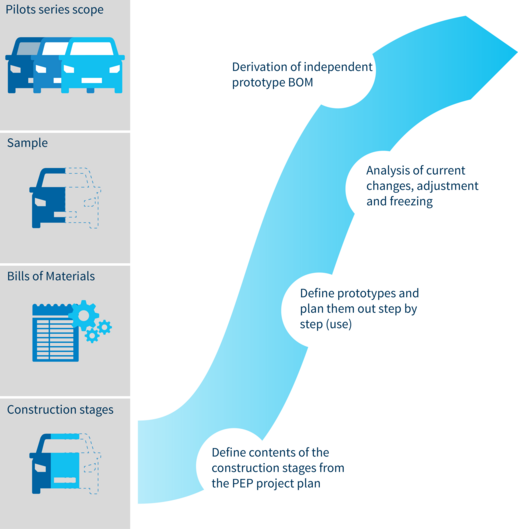

Use a prototype BOM to plan your materials requirements precisely and to schedule

Test Management & Ramp-up starts with the definition of the required prototypes and supports step-by-step the concretization and planning of required units. The core of the documentation is a prototype bill of materials (BOM) that is independent of the development bill of materials and series specifications. This also allows, for example, partial assemblies or the use of predecessor parts and can be structured in detail down to the specimen level. Changes can be easily and reliably reconciled between the development and prototype BOMs.

Economical and precise scheduling – on-time availability

The solution offers the possibility to plan prototype parts without series ERP structures. The procurement scopes can be scheduled and grouped into blocks to collect requirements from different prototypes or projects. This enables you to manage deadlines efficiently and exploit economies of scale in procurement. Thanks to CONTACT Catalyst integration technology, data can be seamlessly processed in ERP systems, for example for order processing or feedback from goods receipt.

Use a prototype BOM to plan your materials requirements precisely and to schedule

Test Management & Ramp-up starts with the definition of the required prototypes and supports step-by-step the concretization and planning of required units. The core of the documentation is a prototype bill of materials (BOM) that is independent of the development bill of materials and series specifications. This also allows, for example, partial assemblies or the use of predecessor parts and can be structured in detail down to the specimen level. Changes can be easily and reliably reconciled between the development and prototype BOMs.

Economical and precise scheduling – on-time availability

The solution offers the possibility to plan prototype parts without series ERP structures. The procurement scopes can be scheduled and grouped into blocks to collect requirements from different prototypes or projects. This enables you to manage deadlines efficiently and exploit economies of scale in procurement. Thanks to CONTACT Catalyst integration technology, data can be seamlessly processed in ERP systems, for example for order processing or feedback from goods receipt.

Test Management & Ramp-up starts with the definition of the required prototypes and supports step-by-step the concretization and planning of required units. The core of the documentation is a prototype bill of materials (BOM) that is independent of the development bill of materials and series specifications. This also allows, for example, partial assemblies or the use of predecessor parts and can be structured in detail down to the specimen level. Changes can be easily and reliably reconciled between the development and prototype BOMs.

Economical and precise scheduling – on-time availability

The solution offers the possibility to plan prototype parts without series ERP structures. The procurement scopes can be scheduled and grouped into blocks to collect requirements from different prototypes or projects. This enables you to manage deadlines efficiently and exploit economies of scale in procurement. Thanks to CONTACT Catalyst integration technology, data can be seamlessly processed in ERP systems, for example for order processing or feedback from goods receipt.

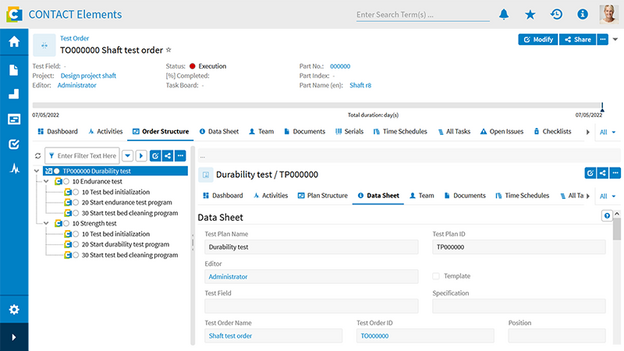

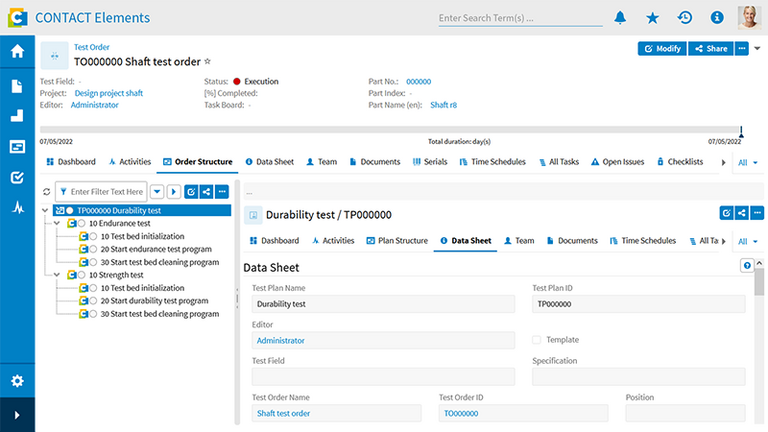

Control and document activities in prototyping and testing

The solution supports all tasks related to tests and prototypes with project management functions such as scheduling and resource planning, task management and release mechanisms in a process-safe manner. You can individually control and precisely document individual activities with reference to samples and prototypes: from parts procurement to activities in tool and sample construction to test results. On this basis, you realize a lifecycle documentation of samples and prototypes.

Comprehensive test management

You organize the tests for individual samples and prototypes efficiently with templates and visual support. Our solution enables the linking of requirements and acceptance criteria as well as direct evaluation in the context of the tests. On the basis of identifiable instances of a generally valid item master record, for example an engine, you can assign different tests for different prototypes to the engine test object and document the results individually. It is also possible to manage test-specific resources such as plants, test benches and personnel in an integrated manner.

The solution supports all tasks related to tests and prototypes with project management functions such as scheduling and resource planning, task management and release mechanisms in a process-safe manner. You can individually control and precisely document individual activities with reference to samples and prototypes: from parts procurement to activities in tool and sample construction to test results. On this basis, you realize a lifecycle documentation of samples and prototypes.

Comprehensive test management

You organize the tests for individual samples and prototypes efficiently with templates and visual support. Our solution enables the linking of requirements and acceptance criteria as well as direct evaluation in the context of the tests. On the basis of identifiable instances of a generally valid item master record, for example an engine, you can assign different tests for different prototypes to the engine test object and document the results individually. It is also possible to manage test-specific resources such as plants, test benches and personnel in an integrated manner.

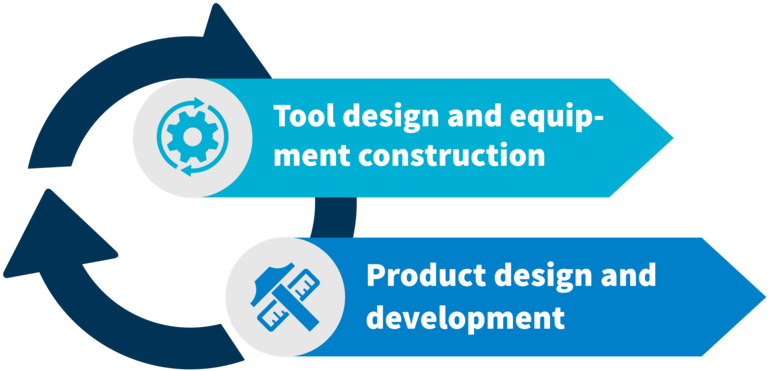

Make relationships between product and tools transparent

The project-based mapping of tools and operating equipment as load carriers with their own bill of materials and reference to the respective engineering BOM rounds off the solution for process control of the series ramp-up. The part reference of tools and operating resources to product components makes the relationships between these normally isolated areas transparent. Relationships between the product and the required tools can be mapped comprehensively. For example, when technical changes are made to the product, you can reliably assign the tool CAD data to the changed product model data. With the help of data reconciliation, any necessary adjustments in toolmaking and production can be implemented without any problems.

Make relationships between product and tools transparent

The project-based mapping of tools and operating equipment as load carriers with their own bill of materials and reference to the respective engineering BOM rounds off the solution for process control of the series ramp-up. The part reference of tools and operating resources to product components makes the relationships between these normally isolated areas transparent. Relationships between the product and the required tools can be mapped comprehensively. For example, when technical changes are made to the product, you can reliably assign the tool CAD data to the changed product model data. With the help of data reconciliation, any necessary adjustments in toolmaking and production can be implemented without any problems.

The project-based mapping of tools and operating equipment as load carriers with their own bill of materials and reference to the respective engineering BOM rounds off the solution for process control of the series ramp-up. The part reference of tools and operating resources to product components makes the relationships between these normally isolated areas transparent. Relationships between the product and the required tools can be mapped comprehensively. For example, when technical changes are made to the product, you can reliably assign the tool CAD data to the changed product model data. With the help of data reconciliation, any necessary adjustments in toolmaking and production can be implemented without any problems.

From virtual product to smooth series ramp-up

Pre-series represents the path from the virtual product model via samples, prototypes and tests to the start of production (SOP). In this phase, it is necessary to define sample scopes, schedule pre-series parts, control prototyping and testing, and synchronize toolmaking. CONTACT Elements Test Management & Ramp-up offers unique support for the series ramp-up processes. The solution stands for transparency and security in a transition phase between the different process and system worlds of development and production.

Related Elements

Ensure a smooth transition to manufacturing with early work planning

Seamless transition between development and manufacturing thanks to work planning in the PLM system

Reliable transfer of the changes made to engineering BOMs to production

Direct transfer of work plans for processing production orders

Ideal coordination between tool design and product development

Make relationships between products and tools transparent

Shorten time to market by parallelizing design and work preparation

Avoid delays to the start of production and additional costs with integrated project management

Seamless integration of suppliers

Efficiently create product architectures and structures

Develop requirements-oriented products

Create mechatronic product structures for systems engineering

Configure variants with 150% BOMs

Manage BOMs and ensuring compliance

Use reliable interfaces between development and production

Accelerate product development through intelligent management of simulation data and processes

Make simulation processes available company-wide with best practices

Automate processes without programming effort

Save time and reduce errors by integrating the CAD and CAE process chains

Fast and reliable synchronization of engineering and manufacturing BOMs

Efficient interaction between development and production planning

Fast and safe elimination of quantity differences

Synchronization with other parts lists for service, spare parts and maintenance

Reliably evaluate deviations directly in the 3D model

Further information

Would you like to know more about this topic? Choose from one of the following information offers.