Press release - February 25, 2020

CONTACT Software and Mitsubishi Electric realize Smart Factory solutions

Production systems collect numerous operating data. Their consistent analysis helps to increase the process excellence in a factory. At a trade press conference, CONTACT Software and Mitsubishi Electric demonstrated how shop floor and corporate IT can be intelligently networked and what advantages this brings for users.

The “Smart Factory” gives industry the option of optimizing processes and products in a targeted manner, adapting them to individual or changing customer requirements without great effort and maintaining their plants with foresight. A prerequisite for this is that production systems are connected to each other and to central services via the Industrial Internet of Things (IIoT).

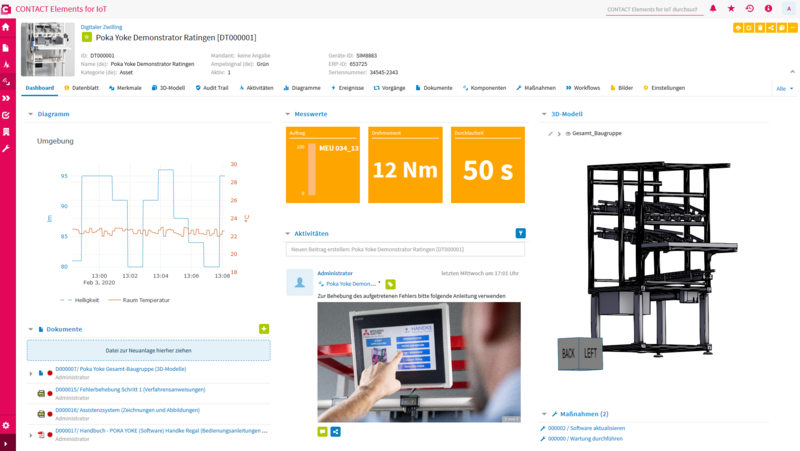

CONTACT Software, as an IIoT partner of Mitsubishi Electric, offers the necessary technology and application modules with its open low-code platform Elements for IoT. Here, the Digital Twin is at the heart of the new, data-driven business processes. In February, both partners explained to the trade press how they are already implementing solutions for the smart factory for Mitsubishi Electric customers.

The Digital Twin visualizes the operating data analyses, shows critical deviations, gives indications of impending errors and triggers appropriate measures. CONTACT ensures the consistency of the Digital Twin by integrating the shop floor and other process-relevant IT systems such as ERP, MES or PLM. Enriched with performance data, plant statuses, manufacturer information or error documentation, new applications are created for holistic production and process optimization.

CONTACT and Mitsubishi Electric use the open software of the non-profit organization Edgecross Consortium to enable the production lines in a factory to communicate with each other. Via this, all protocols and signals of the machines and their components are forwarded to an industrial gateway and converted into an MQTT protocol.

Using this retrofit approach, all devices in a shop floor - regardless of manufacturer, age or functionality - can be connected and processed in the CONTACT Elements for IoT platform. With a Digital Twin plus industrial gateway, Mitsubishi Electric offers an attractive starter package that gives its customers the opportunity to implement individual IIoT solutions for the shop floor quickly and flexibly.