Engineering transformation in the age of digitalization

Smart products for Industry 4.0 and the Internet of Things (IoT) are the basis for new business models and services. They require companies to rethink and redesign their development processes. A new team at CONTACT provides valuable support.

CONTACT Software has built up a new team in the Product Management & Consulting department with meanwhile 15 employees. Its name is its mission: Engineering Transformation. "Our goal is to advance the digital change in the industry," says team leader Dr. Patrick Müller. "To this end, we evaluate new development methods for smart products and implement innovative applications for the PDP and the digital twin in our CONTACT Elements platform.”

The fields of action

CONTACT's Product Management has the task of continuously updating the company's product roadmap with regard to new market requirements. Within this framework, Müller's team is primarily responsible for research strategies, technology transfer into pre-development and PLM method consulting in customer projects.

CONTACT's engineering experts bridge the gap between science and practice in order to equip customers for new challenges: They identify important future topics, carry out research projects and studies, participate in standardization committees and are present at specialist events.

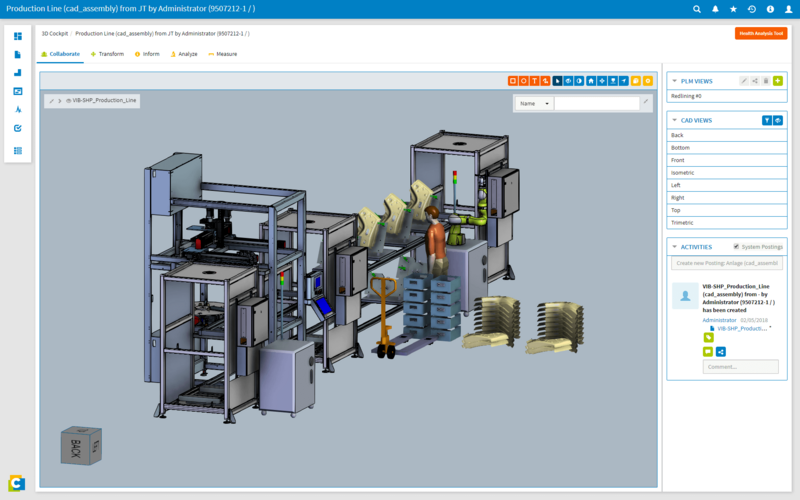

Internally, the team uses two laboratories to design and test prototypes for new PLM and IoT apps. This is followed by test environments in external laboratories and application development for customers.

The topics

With regard to development methods, the Engineering Transformation Team is working on anchoring model-based systems engineering (MBSE) even more deeply in the practice of PLM processes. The focus is on questions relating to model management, collaboration, process design and the connections to modeling requirements and to the product architecture in PLM. With customers, CONTACT also qualifies new processes for systems engineering in the automotive sector.

Another success factor for the manufacturing industry is the closed-loop systems engineering, which aims at the realization of the shortest possible development cycles. The core idea is fast, digitized information flows, for example on product changes or product usage, and short access processes for product components (warranty processing, rotation stocks, material recovery). Agile methods underline this approach at the operational level.

Under the keyword "Twin-in-the-Loop", CONTACT has already presented the advantages associated with such processes. A scenario realized with the Elements platform and model-based methods shows how the digital twin of a product is validated by a model-based simulation.

"In the classic PLM environment, we have methodically and technically revised variant management, classification, the production parts list and requirements management," says Müller. These Elements enhancements accelerate engineering-to-order processes, increase process compliance and traceability, and improve the quality of master data.

Test data management, measurement data management (3D scan data) and virtual commissioning are further topics on which Müller's team is currently working. In these cases, too, the methods are technically based on CONTACT Elements.

Applied research

The previous research activities on Industry 4.0 have resulted in new R&D projects for smart products and services. This year, several projects are underway in the area of industrial IoT, involving new technologies in the field of artificial intelligence or simulation. The respective project partners have specified various digital business models whose IT applications will be implemented with our Elements platform.

The first research project on industrial data analytics started in January. Its consortium aims to create the organizational and technical prerequisites for usage data analyses and their interpretation in order to enable the mechanical and plant engineering industry to carry out targeted retrofit and generation planning for its products. We will report more in one of our next newsletters.