Innovative software for modern machinery and plant engineering

Digitalization is a key requirement in machinery and plant engineering to remain internationally competitive. Modern IT solutions help you tackle current challenges such as the shortage of skilled workers or increasingly complex projects, and resolve the traditional conflict between customer orientation and cost-effectiveness. With CONTACT's software tools, you lay the foundation for your future viability: Digitize your processes consistently, use intelligent process patterns like Configure-to-Order, and improve cross-functional collaboration as well as customer satisfaction with innovative service offerings.

Digitalization is a key requirement in machinery and plant engineering to remain internationally competitive. Modern IT solutions help you tackle current challenges such as the shortage of skilled workers or increasingly complex projects, and resolve the traditional conflict between customer orientation and cost-effectiveness. With CONTACT's software tools, you lay the foundation for your future viability: Digitize your processes consistently, use intelligent process patterns like Configure-to-Order, and improve cross-functional collaboration as well as customer satisfaction with innovative service offerings.

Digitalization is a key requirement in machinery and plant engineering to remain internationally competitive. Modern IT solutions help you tackle current challenges such as the shortage of skilled workers or increasingly complex projects, and resolve the traditional conflict between customer orientation and cost-effectiveness. With CONTACT's software tools, you lay the foundation for your future viability: Digitize your processes consistently, use intelligent process patterns like Configure-to-Order, and improve cross-functional collaboration as well as customer satisfaction with innovative service offerings.

Industry solutions of CONTACT

- Meet delivery deadlines through fast order processing

- Fulfill compliance requirements and quality standards through process security and comprehensive plant documentation

- Make technical change processes seamless with comprehensive system compatibility

- Improve production line availability by minimizing downtime

- Use fleet overview and customer environment documentation as a basis for additional business through digital services

Modern tools for compliance with standards and industry norms

CONTACT Software products help companies in machinery and plant engineering meet standards and design product development processes in accordance with product liability laws. Benefit from solutions for the integration and management of data across the supply chain. Provide all relevant information centrally in the form of a Digital Product Pass. Ensure material compliance through comprehensive material data management and effectively manage your material data according to REACH or RoHS standards.

Software tools for machinery and plant engineering

Syntegon is a leading provider of process and packaging technology for pharmaceuticals and food. After years of successfully using CIM Database at two locations, the special machine manufacturer decided on a global rollout to all of the company's sites. With CONTACT's PLM solution, Syntegon is digitizing and automating its business processes and project execution across the entire value chain. CIM Database also ensures transparency and smooth collaboration in the complex engineer-to-order business.

To the success storyThe ANDRITZ Group is a leading supplier of plants for hydropower, the pulp and paper industry. ANDRITZ METALS has been using CIM Database since 2001 as a digital archive as well as for multi-CAD data management, engineering change management, and transmittal management. Benefits include accelerated and consistent processes from design to order fulfillment, flexible project-specific process design, and easy system adaptability.

To the success storyModernizing the development environment is a challenge – particularly for companies whose plants operate for decades. SIG Combibloc, one of the leading manufacturers of packaging and filling machines for the food industry, successfully managed this migration, future-proofing itself with a new CAD and PLM system. SIG utilizes CIM Database PLM as its master system, which seamlessly integrates with SAP via an interface. The new PLM applications have merged so smoothly into the existing process landscape that SAP users barely noticed the system change.

To the success story"With the CONTACT Elements IoT platform, we were able to clearly increase the efficiency and data quality of our after-sales processes."

Stefanie Weller, Business Process Development Officer at HBC-radiomatic

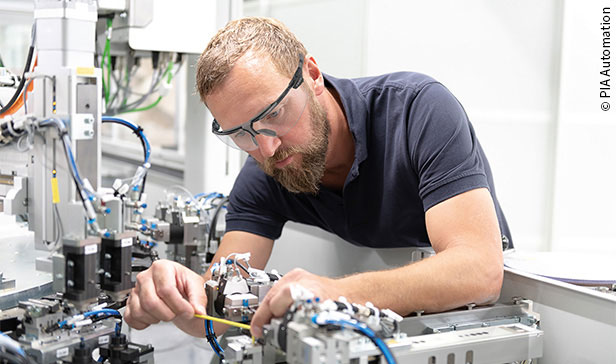

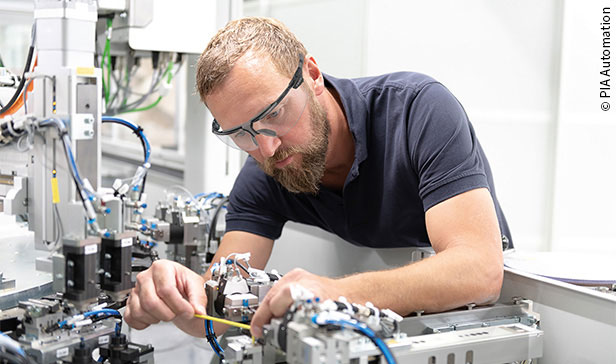

PLM at PIA Automation

PIA Automation develops automation solutions for manufacturing. To enable its globally distributed locations to collaborate on customer projects, the PIA group has implemented our PLM platform CIM Database.

PLM at PIA Automation

PIA Automation develops automation solutions for manufacturing. To enable its globally distributed locations to collaborate on customer projects, the PIA group has implemented our PLM platform CIM Database.

PIA Automation develops automation solutions for manufacturing. To enable its globally distributed locations to collaborate on customer projects, the PIA group has implemented our PLM platform CIM Database.

Software tools for machinery and plant engineering

PLM – Develop machinery and plants faster and more efficiently

With our PLM solution, CIM Database, you can realize end-to-end, digitally controlled development processes. Seamlessly connect all steps from customer requirements to manufacturing engineering and develop machinery and plants significantly faster. System, application, and discipline integration improves collaboration and boosts efficiency. A sophisticated configuration and variant management system helps you manage the increasing complexity of machinery and plants. You can also use operational data in a Closed-Loop Engineering context to continuously improve existing solutions and increase product quality.

Project management – Combining agility and reliability

Project Office combines hybrid project management with classic milestone planning and agile teamwork. Use digital workflows and templates to make your project processes more efficient and complete projects within the planned time and budget. Procedural standards as well as regulatory requirements and documentation obligations – such as those in accordance with the Machinery Directive – are always met. Following the principle of Single Source of Truth, all participants have access to a unified data set, speeding up team collaboration and improving project control.

Industrial IoT – Differentiate yourself from the competition with digital services

With Elements for IoT, you connect your machinery, plants, equipment, and logistics. Leverage the enormous potential of end-to-end automation of your business processes and holistic asset management to differentiate yourself in the service business. With digital twins of your machines and plants, you always have a clear view of the performance of all assets, can ensure high availability, and increase customer satisfaction. High transparency and data quality form the foundation for accelerated service processes – from offers to billing – automated production control, and predictive maintenance. Usage-based billing models and attractive product-service bundles open up additional revenue potential and strengthen customer loyalty.

Collaboration – Smooth collaboration with partners and suppliers

Efficient and secure collaboration with partners and suppliers is the key to successful engineering processes. With intelligent data sharing in the Collaboration Hub, you make this collaboration simpler, more transparent, and more secure. You control and monitor access to CAD models, product structures, variants, and technical changes in cross-company engineering projects. In the Collaboration Hub, teams communicate securely, protect sensitive data with state-of-the-art security standards, and comply with regulatory requirements.

Extend your software with CONTACT Elements

The modular CONTACT Elements platform scales incrementally into a comprehensive solution, covering the entire lifecycle from initial idea to product development, manufacturing, and after-sales. Modern technologies you may only need in a few years can be added as needed.

You want to learn more about our industry focus on machinery & plant engineering?

Find out more from our current news and informations. Choose elements from the most interesting sections.