PredictECO

Product development under consideration of simulation-based sustainability assessment

Faced with resource shortages and climate change, industry needs to develop more sustainable production processes. Green digital twins and digital models enable the simulation and optimization of these processes. Life Cycle Assessment (LCA) plays a key role in assessing the environmental footprint and identifying optimization potential. PredictECO explores an integrated approach to assessing sustainability information in resource-intensive manufacturing processes to support early design decisions regarding their sustainability impact.

- Project start: June 2023

- Runtime: 3 Years

- Funding amount: €8 million

- Number of partners: 7

Objectives

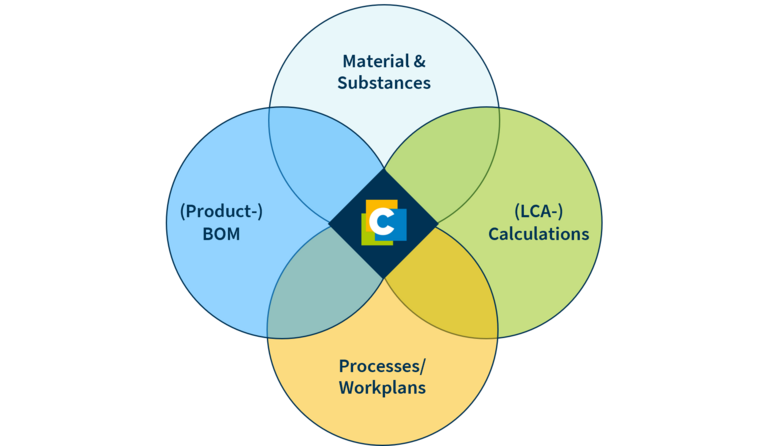

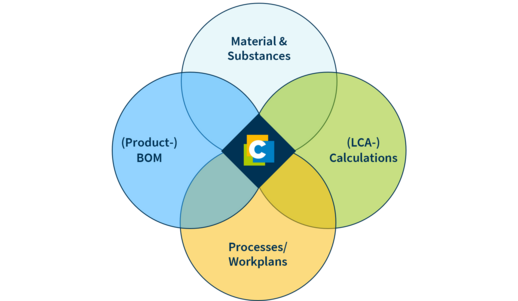

As a consortium partner, CONTACT acts as a solution provider. We use the Elements platform to enable an end-to-end, software-based product development process. This ranges from formalized process descriptions to an integrated sustainability assessment. Within the project, we offer the CIM Database PLM development platform as well as the Elements for IoT system. Our platform already offers comprehensive functions for the Digital Twin and will be extended with new methods and functionalities in the course of the research project:

◾ Development of new methods for the sustainability assessment of resource-intensive manufacturing processes already in the design phase (engineering design).

◾ Supply of the "green digital twin" and the underlying information flows for a sustainability assessment from PLM and IoT.

◾ Establishment of a data structure for a green digital twin and downstream evaluation using LCA-specific software.

◾ Innovative development methods for machine and plant engineering with the aim of being able to safeguard sustainability aspects at an early stage.

Closed-loop engineering for the feedback of knowledge from operation and production back into development.

Objectives

As a consortium partner, CONTACT acts as a solution provider. We use the Elements platform to enable an end-to-end, software-based product development process. This ranges from formalized process descriptions to an integrated sustainability assessment. Within the project, we offer the CIM Database PLM development platform as well as the Elements for IoT system. Our platform already offers comprehensive functions for the Digital Twin and will be extended with new methods and functionalities in the course of the research project:

◾ Development of new methods for the sustainability assessment of resource-intensive manufacturing processes already in the design phase (engineering design).

◾ Supply of the "green digital twin" and the underlying information flows for a sustainability assessment from PLM and IoT.

◾ Establishment of a data structure for a green digital twin and downstream evaluation using LCA-specific software.

◾ Innovative development methods for machine and plant engineering with the aim of being able to safeguard sustainability aspects at an early stage.

Closed-loop engineering for the feedback of knowledge from operation and production back into development.

Objectives

As a consortium partner, CONTACT acts as a solution provider. We use the Elements platform to enable an end-to-end, software-based product development process. This ranges from formalized process descriptions to an integrated sustainability assessment. Within the project, we offer the CIM Database PLM development platform as well as the Elements for IoT system. Our platform already offers comprehensive functions for the Digital Twin and will be extended with new methods and functionalities in the course of the research project:

◾ Development of new methods for the sustainability assessment of resource-intensive manufacturing processes already in the design phase (engineering design).

◾ Supply of the "green digital twin" and the underlying information flows for a sustainability assessment from PLM and IoT.

◾ Establishment of a data structure for a green digital twin and downstream evaluation using LCA-specific software.

◾ Innovative development methods for machine and plant engineering with the aim of being able to safeguard sustainability aspects at an early stage.

Closed-loop engineering for the feedback of knowledge from operation and production back into development.

Motivation

With PredictECO, CONTACT Research is focusing on the acquisition and distribution of sustainability-relevant (process) information within the product life cycle. In this context, the research activities of CONTACT include the development of methodological and technical foundations for the sustainability assessment of products and processes, e.g. in design phases.

Together with industrial application partners, CONTACT is using PredictECO to demonstrate the ability to perform comprehensive integrative sustainability assessments based on PLM-available data and process information. In addition to comprehensive methodological and conceptual knowledge in the area of LCA, customers will benefit in the future from lightweight sustainability assessments (in the sense of a simple entry level). This will enable them to carry out product declarations (e.g. Digital Product Passport), carbon footprints, material compliance, etc. with CONTACT Elements and provide them in their supply chains.

The research project thus makes a decisive contribution to more sustainable production on the basis of digital twins.

Motivation

With PredictECO, CONTACT Research is focusing on the acquisition and distribution of sustainability-relevant (process) information within the product life cycle. In this context, the research activities of CONTACT include the development of methodological and technical foundations for the sustainability assessment of products and processes, e.g. in design phases.

Together with industrial application partners, CONTACT is using PredictECO to demonstrate the ability to perform comprehensive integrative sustainability assessments based on PLM-available data and process information. In addition to comprehensive methodological and conceptual knowledge in the area of LCA, customers will benefit in the future from lightweight sustainability assessments (in the sense of a simple entry level). This will enable them to carry out product declarations (e.g. Digital Product Passport), carbon footprints, material compliance, etc. with CONTACT Elements and provide them in their supply chains.

The research project thus makes a decisive contribution to more sustainable production on the basis of digital twins.

Motivation

With PredictECO, CONTACT Research is focusing on the acquisition and distribution of sustainability-relevant (process) information within the product life cycle. In this context, the research activities of CONTACT include the development of methodological and technical foundations for the sustainability assessment of products and processes, e.g. in design phases.

Together with industrial application partners, CONTACT is using PredictECO to demonstrate the ability to perform comprehensive integrative sustainability assessments based on PLM-available data and process information. In addition to comprehensive methodological and conceptual knowledge in the area of LCA, customers will benefit in the future from lightweight sustainability assessments (in the sense of a simple entry level). This will enable them to carry out product declarations (e.g. Digital Product Passport), carbon footprints, material compliance, etc. with CONTACT Elements and provide them in their supply chains.

The research project thus makes a decisive contribution to more sustainable production on the basis of digital twins.

Project Partners

This research project is funded by the German Federal Ministry of Economics and Climate Protection (BMWK) and supervised by the project executing organization, the German Aerospace Center (DLR) Division Society, Innovation and Technology.