ESCOM

Balanced Edge Cloud Environments for Sovereign Components-Service Systems in Production Applications

The ESCOM project focuses on the development of balanced edge cloud systems for the production sector. Supported by the German Federal Ministry of Economics and Climate Protection as part of the "Edge Data Economy" technology program, it aims to explore edge computing in industry-specific applications. Another goal is the integration of a Gaia-X compliant data ecosystem. Thanks to an interdisciplinary consortium, we can ensure that all requirements and perspectives of the partners involved are taken into account.

- Project start: January 2022

- Runtime: 3 Years

- Funding amount: €4 million

- Number of partners: 15

Objectives

Technical Overall Concept at ESCOM: Efficiency through Artificial Intelligence

The ESCOM concept combines cutting-edge technologies from the metalworking production sector. Two core scenarios are highlighted, both following a uniform approach: the transformation of expert knowledge from component design into intelligent services.

From Simulation Models to AI Services

Simulation models accurately capture the behavior of production components. They can illustrate both the impact on process quality (Prescriptive Quality) and the wear level of the component (Predictive Maintenance). Using AI methods, these models are turned into services that automatically interpret operational data. This leads to enhanced process quality and targeted maintenance predictions.

AI in the Cloud

The complexity of the models and their time-consuming calculations demand innovative solutions. Through AI-supported methods, these models are optimized in the cloud and provided as services on the edge. This allows companies to immediately benefit from the advantages.

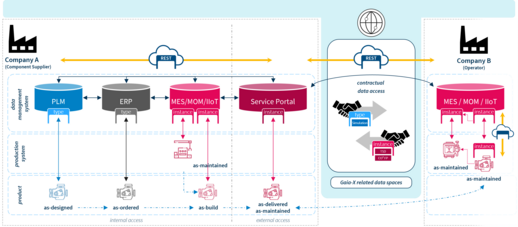

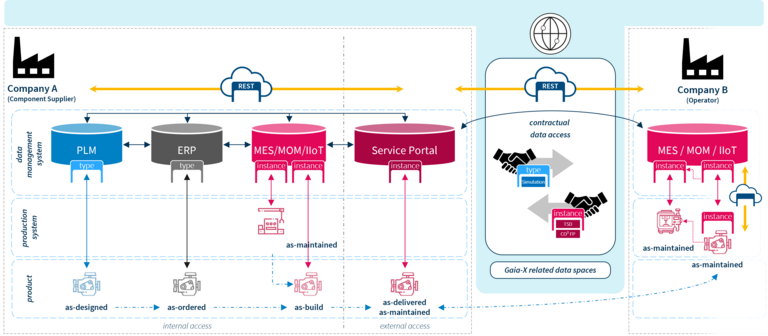

Future-Oriented Data Governance

State-of-the-art technologies are utilized for data transfer. The Asset Administration Shell and its sub-models standardize data content. When exchanging information between different parties, the Gaia-X principles are central, ensuring utmost security and transparency.

Objectives

Technical Overall Concept at ESCOM: Efficiency through Artificial Intelligence

The ESCOM concept combines cutting-edge technologies from the metalworking production sector. Two core scenarios are highlighted, both following a uniform approach: the transformation of expert knowledge from component design into intelligent services.

From Simulation Models to AI Services

Simulation models accurately capture the behavior of production components. They can illustrate both the impact on process quality (Prescriptive Quality) and the wear level of the component (Predictive Maintenance). Using AI methods, these models are turned into services that automatically interpret operational data. This leads to enhanced process quality and targeted maintenance predictions.

AI in the Cloud

The complexity of the models and their time-consuming calculations demand innovative solutions. Through AI-supported methods, these models are optimized in the cloud and provided as services on the edge. This allows companies to immediately benefit from the advantages.

Future-Oriented Data Governance

State-of-the-art technologies are utilized for data transfer. The Asset Administration Shell and its sub-models standardize data content. When exchanging information between different parties, the Gaia-X principles are central, ensuring utmost security and transparency.

Objectives

Technical Overall Concept at ESCOM: Efficiency through Artificial Intelligence

The ESCOM concept combines cutting-edge technologies from the metalworking production sector. Two core scenarios are highlighted, both following a uniform approach: the transformation of expert knowledge from component design into intelligent services.

From Simulation Models to AI Services

Simulation models accurately capture the behavior of production components. They can illustrate both the impact on process quality (Prescriptive Quality) and the wear level of the component (Predictive Maintenance). Using AI methods, these models are turned into services that automatically interpret operational data. This leads to enhanced process quality and targeted maintenance predictions.

AI in the Cloud

The complexity of the models and their time-consuming calculations demand innovative solutions. Through AI-supported methods, these models are optimized in the cloud and provided as services on the edge. This allows companies to immediately benefit from the advantages.

Future-Oriented Data Governance

State-of-the-art technologies are utilized for data transfer. The Asset Administration Shell and its sub-models standardize data content. When exchanging information between different parties, the Gaia-X principles are central, ensuring utmost security and transparency.

Motivation

In ESCOM, CONTACT Research is leveraging the potential of the "Data Service Ecosystems" research area in order to decisively foster the digital transformation through innovative data and service ecosystems and to open up new opportunities for manufacturing companies in their interaction with digital data. In this context, data sovereignty is at the heart of our efforts.

In terms of CONTACT Elements, we focus on integrating the latest technologies in this regard. In this way, ESCOM offers direct, future-proof added value for our customers in the area of information exchange (e.g. on the basis of Gaia-X principles) between enterprise data management systems using standardized Asset Administration Shells (AAS). By connecting to Gaia-X, we expect improved data sovereignty, transparency and interoperable data exchange for our customers.

Motivation

In ESCOM, CONTACT Research is leveraging the potential of the "Data Service Ecosystems" research area in order to decisively foster the digital transformation through innovative data and service ecosystems and to open up new opportunities for manufacturing companies in their interaction with digital data. In this context, data sovereignty is at the heart of our efforts.

In terms of CONTACT Elements, we focus on integrating the latest technologies in this regard. In this way, ESCOM offers direct, future-proof added value for our customers in the area of information exchange (e.g. on the basis of Gaia-X principles) between enterprise data management systems using standardized Asset Administration Shells (AAS). By connecting to Gaia-X, we expect improved data sovereignty, transparency and interoperable data exchange for our customers.

Motivation

In ESCOM, CONTACT Research is leveraging the potential of the "Data Service Ecosystems" research area in order to decisively foster the digital transformation through innovative data and service ecosystems and to open up new opportunities for manufacturing companies in their interaction with digital data. In this context, data sovereignty is at the heart of our efforts.

In terms of CONTACT Elements, we focus on integrating the latest technologies in this regard. In this way, ESCOM offers direct, future-proof added value for our customers in the area of information exchange (e.g. on the basis of Gaia-X principles) between enterprise data management systems using standardized Asset Administration Shells (AAS). By connecting to Gaia-X, we expect improved data sovereignty, transparency and interoperable data exchange for our customers.

Project Partners

Development of Digital Technologies in the Edge Data Economy