Press Release – September 24, 2025

New study shows the future of holistic digital factory models

Fraunhofer IGCV, CONTACT Software, and Ingenics Consulting have evaluated the results of a study conducted with five partners on holistic digital factory models.

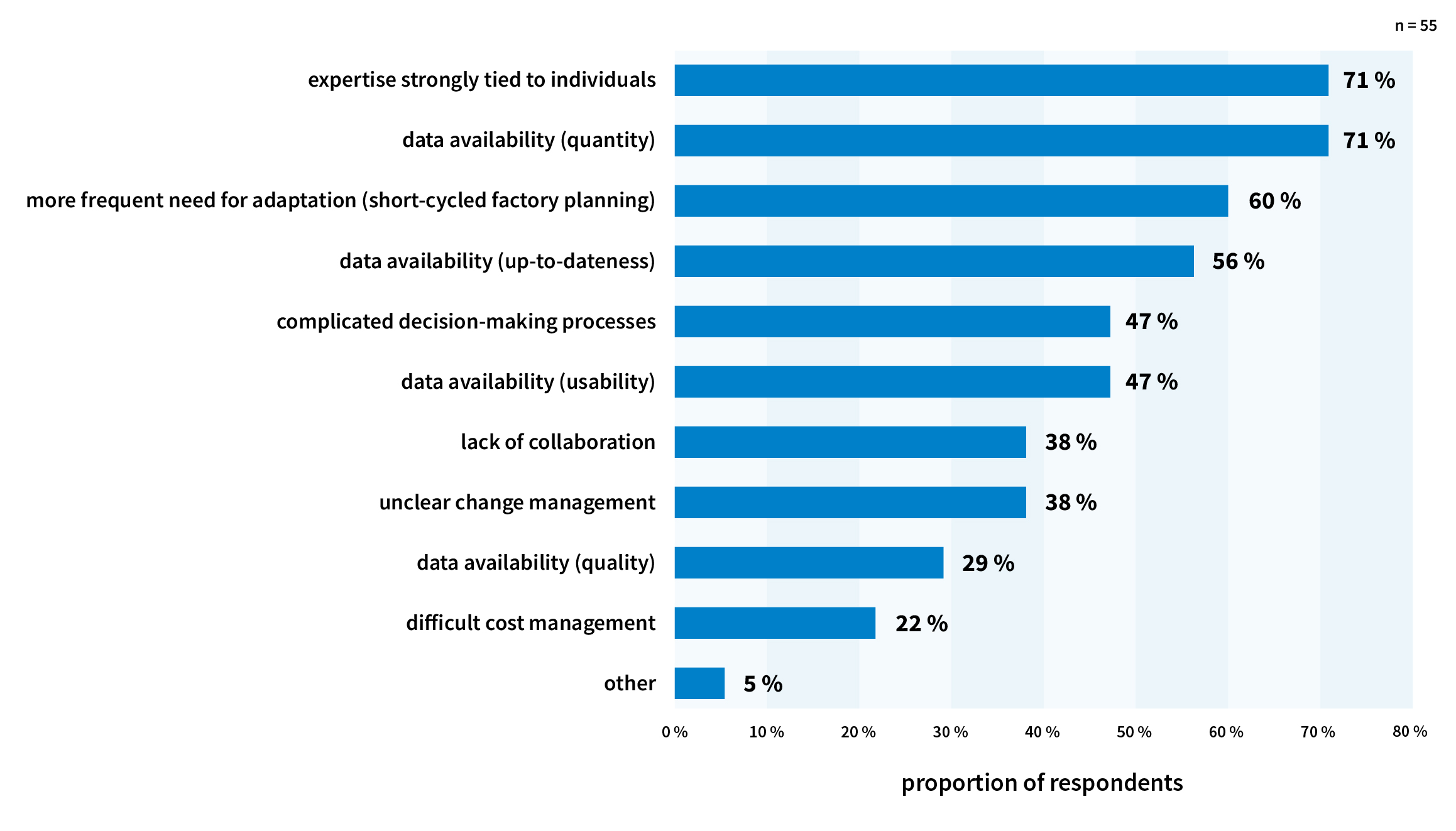

New demands and growing competitive pressure are forcing companies to adapt their factories more frequently. The new study “Holistic Digital Factory Models” identifies the resulting challenges and presents solutions for factory operators through eight key theses. Doctoral candidates in the field of factory planning assessed these solutions based on the current state of research in literature.

A key finding is the transformation of factory planning: it is evolving into a continuous, short-cycle task, which makes a seamless information flow across the entire lifecycle essential.

Literature and experts agree that there is currently a lack of collaboration and seamless information exchange between the building and production system domains. The participants discussed incentives and methods to improve the situation, such as Building Information Modeling (BIM). Whether Common Data Environments (CDE) are necessary remains an open question, as participants also consider interfaces to be sufficient.

Experts confirmed the hypothesis that while companies primarily rely on Office and CAD software today, simulation tools, BIM, and PLM software will increasingly complement these in the future. The role of digital twins in factory planning was assessed as ambiguous, although the relevance of static and dynamic data was emphasized. Regarding the Industrial Metaverse, there was consensus that it is still too underexplored for practical applications in factory planning.

In conclusion, the experts underscored that standardizing factory planning processes remains a significant challenge. While the literature offers methods, experts find them either unfamiliar or insufficient. Furthermore, companies would need to customize generic methods individually to their specific needs and implement them as a company-wide standard.

For the authors, this points out the need for further research. This applies in particular to cross-lifecycle information consistency, the effective use of digital twins for factory planners, and the potential of the Industrial Metaverse. Additionally, it is necessary to further develop existing specialized processes and methods. This development is already underway at organizations like buildingSMART Germany e.V. and VDI (Verein Deutscher Ingenieure e. V., Association of German Engineers).

The detailed study results are available here.