Press release - September 18, 2025

BINDER Fördertechnik delivers customized solutions faster with CIM Database PLM

With CONTACT Elements as its central information platform, BINDER Fördertechnik is driving its digital transformation forward. The machinery manufacturer is now replacing its previous solution and is automating complex processes with CIM Database PLM.

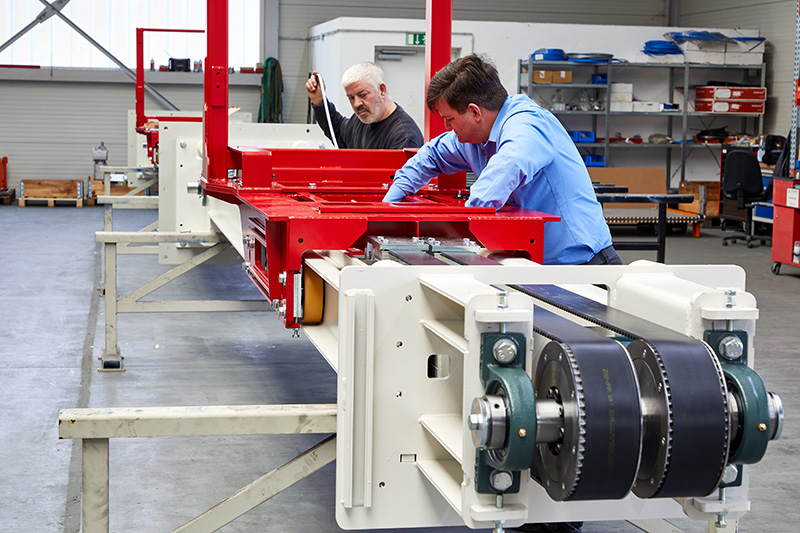

BINDER develops modern conveyor technology solutions tailored to its customers’ individual needs. The mechanical engineering experts take into account the intended application and related aspects such as material selection, adaptation to the size and weight of the conveyed goods, and the resource-efficient operation of the systems. To meet customer requirements for documentation, a consistent database is essential.

In the past, BINDER used keytech PLM/DMS for this purpose and is now replacing that system with CIM Database PLM from CONTACT Software. This allows the company to break down data silos and ensure transparent, more streamlined processes. With the PLM solution, BINDER aims to accelerate its digital transformation, involving all departments in the process. For the bidirectional exchange of part master data, CONTACT is integrating the abas ERP system as well as SolidWorks.

“CONTACT will help us to further digitalize our processes and find solutions that are perfectly tailored to our specific needs,” says Rudolf Haberl, Head of Engineering and Project Planning at BINDER Fördertechnik. For example, some customizations from the previous system, such as the determination of sheet metal thicknesses, will also be implemented in CIM Database.

In the second phase, BINDER plans to implement variant management as well as digitalize and expand service operations with CONTACT Elements for IoT. The smart services solution will help the company respond flexibly to requirements, thereby increasing customer satisfaction. The option to easily switch to a cloud instance later on also convinced BINDER.

BINDER Fördertechnik has been developing future-proof solutions for conveyor and material handling technology for over 50 years. The company, headquartered in Burgstetten near Stuttgart, Germany, also offers individual custom solutions. With 60 employees, the machinery manufacturer generated approximately 15 million Euros in revenue in 2024.