Closed-loop engineering for strategic product planning

Industry 4.0 can provide machine and plant engineering with valid data for product improvements. The DizRuPT research project uses various demonstrators to show how manufacturers can plan and realize a retrofit or the next generation in a targeted manner by analyzing operating data. Here we present initial results from the field.

The DizRuPt research project can refer to a heterogeneous product portfolio of industrial partners from various sizes and a wide range of sectors: Ventilation systems for buildings, which consist mainly of purchased parts (Westaflex). Complex ATMs that are regarded as closed systems and made intelligent via external sensors (Diebold Nixdorf). Hydraulic forging hammers weighing tons that, in the worst case, self-destruct due to extreme forces if problems are discovered too late (Lasco), and fieldbus couplers that ensure communication between automation systems in production (Weidmüller).

These companies are validating the research results using individually defined use cases. Today, we present one of the pilot applications for data-driven retrofit and generation planning in more detail.

Practical scenario fieldbus coupler

Fieldbus couplers support system integration in the production process by connecting sensors and actuators (field devices) with programmable logic controllers (PLCs) to ensure data continuity along the various levels of automation. During the DizRuPT project, two product hypotheses crystallized for their manufacturer to pursue.

One assumption was that the application range is too narrowly defined due to the specified operating temperatures. Customers therefore do not use the product, even though it is operated at more extreme temperatures. In addition, the installation of the fieldbus couplers is adjusted during operation with regard to the connected sensors and actuators, but the technical changes and their timing are only recorded sporadically. The lack of traceability led to the second assumption that continuous data logging in the digital twin would shorten the time between potential problem detection and resolution and improve customer support.

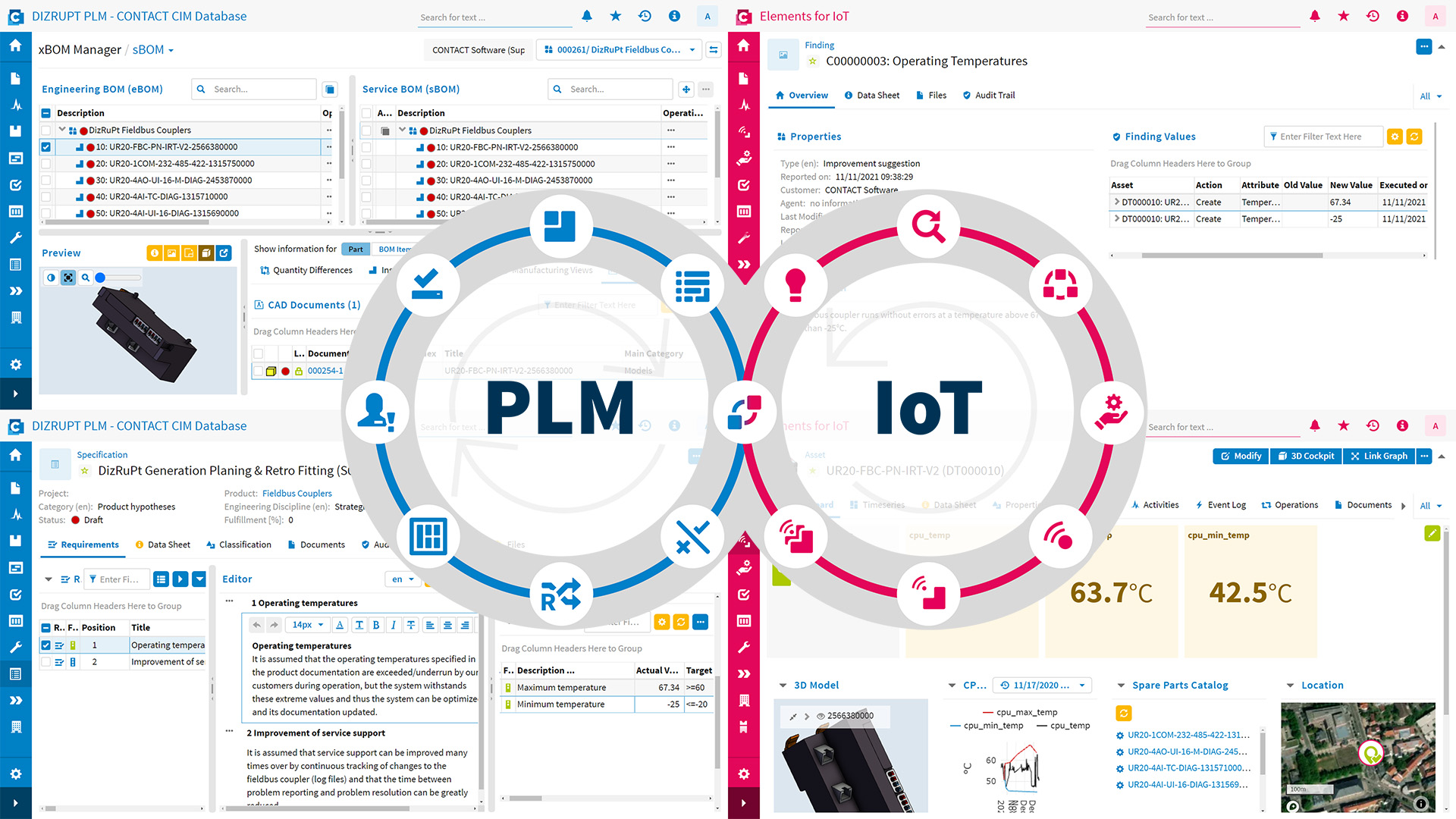

Together with the manufacturer, a demo system based on the CONTACT Elements platform was built to test these two hypotheses.

Methodology and software implementation

First, a template for the digital twin is derived from the virtual product model, which is then used to instantiate assets for the devices in the field on the IoT platform. The engineering bill of materials becomes a service bill of materials (sBOM) with classified asset-relevant components. Synchronization between the PLM and IoT applications derives a component structure (aBOM) from the sBOM. BOM items that have not been marked as asset-relevant are nevertheless managed as spare or wear parts in the digital twin for any subsequent service cases. By connecting the real field devices, usage data can be collected, visualized and processed. This data serves as the basis for analyses or for triggering MRO processes.

Manufacturers can perform analyses for individual assets as well as for fleets. The results - for example, the maximum and minimum temperature under which the fieldbus couplers operate - can be further processed as KPIs. The resulting insights flow from the IoT platform back into the PLM system for further product planning and optimization. Due to data continuity and traceability, the event object is linked to the virtual product model and can be used to validate product hypotheses.

The example shows that the fieldbus couplers work without errors even at higher operating temperatures than assumed, so that the acceptance criterion is automatically evaluated as positive and applicable. The manufacturer can then optimize the product by making a technical change with subsequent impact analysis or develop new business models based on the customer operating data.

Conclusion

A smart networked asset and its population deliver vast amounts of data that can show how customers really use a product. The organizational and technical processes implemented in the DizRuPt project allow more precise conclusions to be drawn about what current and future product generations should provide. Explorative data analyses can also be used to identify previously unknown correlations and thus answer the question of which components fail frequently and why this happens.

Manufacturers can use such findings to better decide whether to optimize assets on the market by a retrofit or to plan certain functions for the further development of their products. The project results will generate high benefits not least through their transferability to other industries such as vehicle construction or infrastructure projects.

Maintained by: