Variant Management: more in it for Build-to-Order Manufacturing

The CIM DATABASE module for variant management helps companies organize their product portfolios more efficiently and cost-effectively. The solution supports rule-based variant configuration, working with maximum and variant BOMs, CAD integration and the 3D visualization of product variants. Its new version address requirements relating to electrical design and plant engineering in particular.

Organizing products into product lines and explicit variants in the context of cross-disciplinary product line engineering is a widely used means of meeting individual customer requirements quickly and on competitive terms. In the automotive industry, the product variability dictated by OEMs means that efficient variant management is also becoming increasingly important for the suppliers of product components.

In the field of plant engineering, there is a growing interest in modular, mechatronic systems that allow the advantages of different product strategies to be combined. The aim here is to combine the speed and positive cost effects of a configure-to-order (CTO) approach with the flexibility that this industry requires for customer-specific product adaptations in customer projects (engineer-to-order/ETO).

CIM DATABASE PLM provides a variant management tool that allows users to describe modular product systems and individual product variants in the early phase of digital development. The solution is built around the property-based modeling of product variability. It supports the precise definition of the required solution space as well as the detailed configuration and validation of individual product variants. The variant management solution was extended in 2016 with primary focus placed on users in the fields of plant and electrical/electronic engineering (E/E). We briefly present the main use cases and innovations below.

Different variant views

Users in the field of plant engineering are provided with new methods for combing CTO and ETO approaches in an end-to-end process. The view of a filtered (maximum) BOM allows for the fast configuration of the products and the creation of a persistent BOM. In the engineer-to-order business, the variant BOM can be tailored to meet customer-specific requirements, even if it was adapted from a modular system with an over-defined BOM and a set of rules.

The variant editor

The variant editor allows users to define variants and access the BOM, CAD models, etc. Filters, which are applied to the values for product features, can be used to restrict the list of variants displayed in the editor's tabular view. Even large variant spaces can easily be explored using the variant editor.

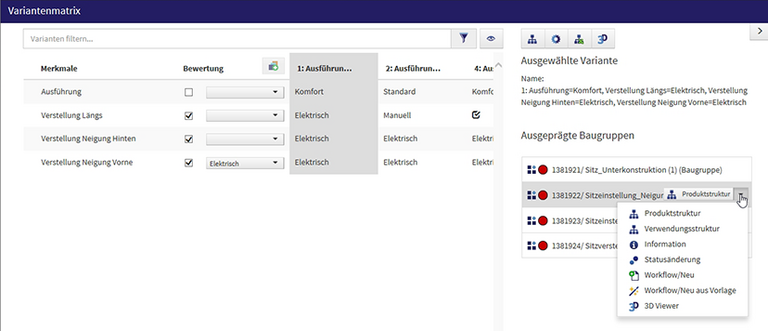

The variant matrix

The new variant matrix, on the other hand, focuses on the feature space. In line with the work methods employed in electrical design, variable components and supplementary options are linked with hierarchical property structures to provide ECAD users with better access to variant control. The product properties are displayed in a tree structure, which can be used to define new product variants or filter existing variants. The variant matrix is suitable for exploring large feature spaces.

The variant matrix

The new variant matrix, on the other hand, focuses on the feature space. In line with the work methods employed in electrical design, variable components and supplementary options are linked with hierarchical property structures to provide ECAD users with better access to variant control. The product properties are displayed in a tree structure, which can be used to define new product variants or filter existing variants. The variant matrix is suitable for exploring large feature spaces.

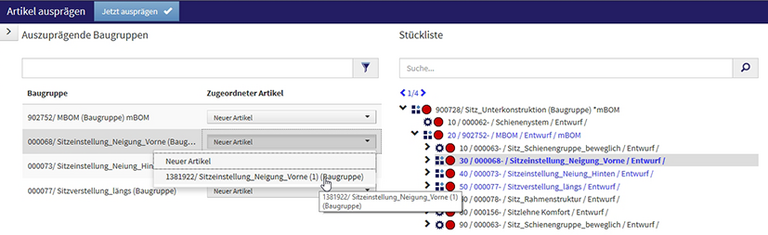

The BOM wizard

The BOM wizard helps users store variant BOMs persistently in the database. This is useful when a modular system is used to define variants that need to be processed in downstream processes such as testing, prototype construction, customization in the context of engineer-to-order business, etc.

The BOM wizard

The BOM wizard helps users store variant BOMs persistently in the database. This is useful when a modular system is used to define variants that need to be processed in downstream processes such as testing, prototype construction, customization in the context of engineer-to-order business, etc.

Users can use this tool to generate a new BOM automatically or with manual intervention. Search and navigation functions provide support when creating new articles or incorporating suitable variant articles with appropriate features from the database.

We have also developed an algorithm that makes it much easier to generate new part numbers for variable assemblies, even if the variance has been modeled over the course of numerous BOM levels.

Conclusion

The rising number of variants coupled with growing product complexity is putting huge pressure on manufacturers to define variants within the development process, validate them and communicate them to downstream departments and processes efficiently using one and the same medium.

PLM-assisted variant management that integrates CAD and ERP and allows for industry-specific work methods offers companies substantial value-added effects: more efficient creation of product data (drawings, BOMs, order documentation, article master data), a higher reuse rate, cost savings and rapid product creation process.

Contact: Dr. Patrick Müller, PLM Product Manager